100% Original Plastic Recycling Shredder - LB- PP/PE Film/Bag/Rigid scraps Washing& Recycling Line – Langbo

100% Original Plastic Recycling Shredder - LB- PP/PE Film/Bag/Rigid scraps Washing& Recycling Line – Langbo Detail:

LB Machinery PP/PE Film/Bag/Rigid scraps Washing& Recycling Line

PP/PE Film and bag is pervasive in our life. Meanwhile, it is an important part in the plastic recycling and processing industry. Through crushing the wasted film/Bag, we obtain small particle scrapes. After cold and hot water washing, we acquire clean and soft flakes or rigid scraps. Those clean scrapes is used for the next application. The process and re-sale is economical and eco-friendly which is a promising business.

Langbo Machinery has over 12 years experience in the LB Machinery PP/PE Film/Bag/Rigid scraps Washing& Recycling Line. We offer the recycling line to industry worldwide, and our recycling program is designed to reduce operating costs and obtain quality PET flakes.

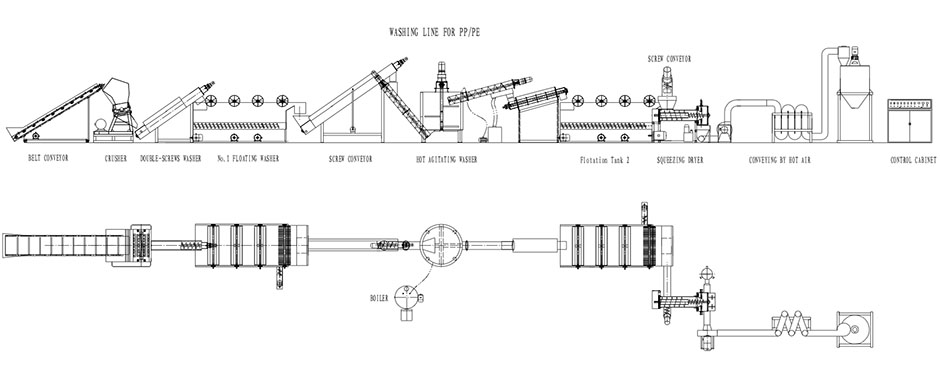

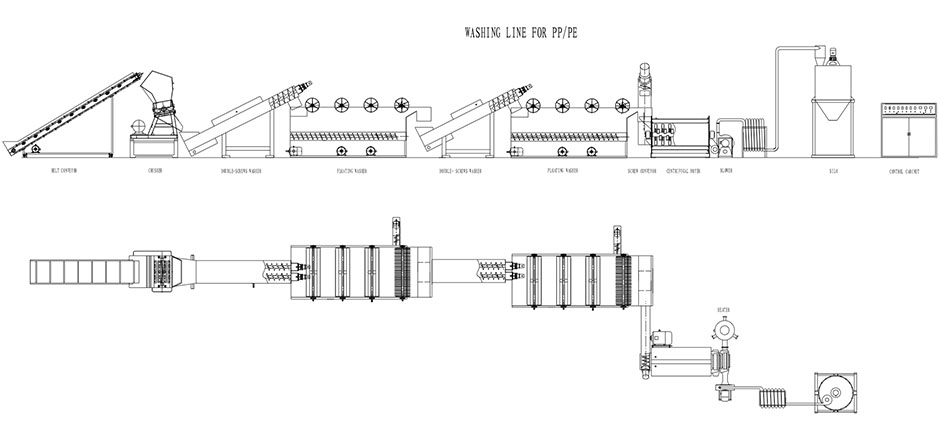

The processing procedure of the complete washing line consists of conveying – crushing – floating washer with cold water – agitating washer with hot water – floating washer with cold water – centrifugal drying/squeezing drying – collection.

➢ Belt conveyor

➢ Shredder&crusher

➢ Hot Washer

➢ Centrifugal Dryer

➢ Cold Washer

➢ Floating Washer

➢ Collection

➢ Applicable material: PP, HDPE, LDPE, LLDPE, etc..

➢ Materials shape: woven bag, printed films, agricultural film, raffia and rigid scraps.

The production capacity can be 300kg/hr, 500kg/hr, 1000kg/hr.

Note: Depending on material shape, some units involved in complete line will be changed and available.

Complete washing & recycling line

Crusher recycling

Double screw friction washer recycling

Floating cold washer recycling

Friction and hot washing

Product detail pictures:

Related Product Guide:

Our commission is to serve our buyers and purchasers with effective good quality and aggressive portable digital goods for 100% Original Plastic Recycling Shredder - LB- PP/PE Film/Bag/Rigid scraps Washing& Recycling Line – Langbo, The product will supply to all over the world, such as: Mexico, Hongkong, Naples, If you give us a list of merchandise you are interested in, along with makes and models, we can send you quotations. Remember to email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.