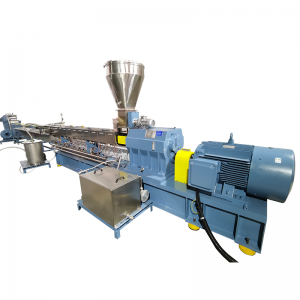

400KG/H PVC Pelletizing Line/Machine/PVC Granulating Line

1.Application

With different designs of screw, this machine can be applied to granulate the recycled material of rigid PVC, soft PVC and waste PVC. It can be stopless in the course of production.

It used pneumatic conversion and strong-wind blowing. At the same time can adjust stainless steel

storage container and can run at high speed for a long time while extrude stably.

2.Features

1,advanced equipment, precise pelletizing and high producing capacity.

2, Conical double-screw extruder, very suitable to process PVC powder with high capacity

3, Pelletizing style: Hot-cutting on mould face, even cutting ensures good shape.

4,Auxiliary machine: Pellets cooling & classifying

Process flow:

Raw material+ additive → Mixing → Conveying feeding → hopper feeding → Conical twin screw extruder → Hot face cutting → Cyclone separator → Vibration sieve → Blowing system → Storage hopper → Finished product packing

Technique parameter

| Model number | Screw diameter (mm) | Rotational speed of screw (rpm) | Pellets size(mm) | Main motor power (kw) | Heating power of Barrel (kw) | Production capacity (kg/h) | Central height of machine (mm) | Net weight | Overall size (mm) |

| SJSZ45 | 45/90 | 1-45 | 3-4mm | 15 | 9.6 | 70-80 | 1000 | 2800 | 3300*1200*2000 |

| SJSZ51 | 51/105 | 1-45.5 | 3-4mm | 22 | 11.5 | 80-120 | 1000 | 3000 | 3360*1290*2100 |

| SJSZ55 | 55/110 | 1-40 | 3-4mm | 22 | 18 | 150-180 | 1000 | 3500 | 3620*1350*2200 |

| SJSZ65 | 65/132 | 1-38 | 3-4mm | 37 | 24 | 250-300 | 1000 | 4000 | 4235*1520*2450 |

| SJSZ80 | 80/156 | 1-36.9 | 3-4mm | 55 | 36 | 320-450 | 1000 | 5000 | 4750*1550*2460 |

| SJSZ92 | 92/188 | 1-34.7 | 3-4mm | 110 | 88 | 650-800 | 1000 | 5500 | 6000*1600*2500 |

Our factory

Are you a trading company or factory? Can I have a factory visiting?

We are a factory that produces machines for customers directly. Yes, our production plant can be visited at any time. We are in Zhangjiagang, Jiangsu Province close to Shanghai and Wuxi. If you are near to us, the pick-up service is available.

How to build trust with Langbo

We can send working videos showing the machine running perfectly in several countries for online communication. We will provide customer-focused and tailored technical suggestions.

For offline contact, you can visit our factory and talk about the machine face to face, you can find our competence in the field of plastic extrusion and tell our ability in machine building.

Is the shipping cost included in the quotation?

Usually, our quotation contains FOB Shanghai as a shipment condition. This means the shipping cost between the delivery and destination ports will not be included in the quotation. The shipping cost fluctuates according to the delivery company and shipping date. Langbo can help customers to get the latest shipping price. Customers decide if we add the shipping cost to the quotation or choose a shipping agent by themselves.

What will happen after order confirmation

confirmation of Configuration

Sign of Proforma invoice

30% of total price pre-payment for production starting

Test running in the house, customers on-site or video connecting

Confirmation of machine condition

70% of the total price for delivery preparation

Confirmation of Delivery date

Shipping to customer

On-site commissioning

Training in machine operation and maintenance

Confirmation of handover

One year guarantee

Whole lifecycle service and technical support

What is the Payment Method?

T/T, D/P, Letter of credit, Cash transaction

How to guarantee the machine quality made by Langbo

We provide one year guarantee and whole-lifecycle technical support for our product. During in-house test running, customers can check the machine on-site. Any point for optimization will be done immediately.

How can customers get the exact machine as they wish?

Factory visiting before order

Product sample posting to Langbo for a better understanding of customer's expectations and configuration communication

On-site checking during test running

Do you have CE Certification?

Yes. Both our extrusion machine and plastic recycling machine have CE Certification.

What is the delivery time between order confirmation and delivery?

Usually 45 days. Depended on the certain project, the exact delivery time will be wrote on contract.

What are services for after-sale

One-year quality guarantee.

Quick response for technical support

Problem analysis for production problems

What means one-year quality guarantee

After the handover of the machine, Langbo provides free new parts for every non-man-made damage.

How to get the required area of the machine?

For a new plant, you can contact me. (whatsapp) After knowing your demand, I can make the detailed solution and layout of the machine line. Meanwhile, I will provide technical guidance of your installation and specification.