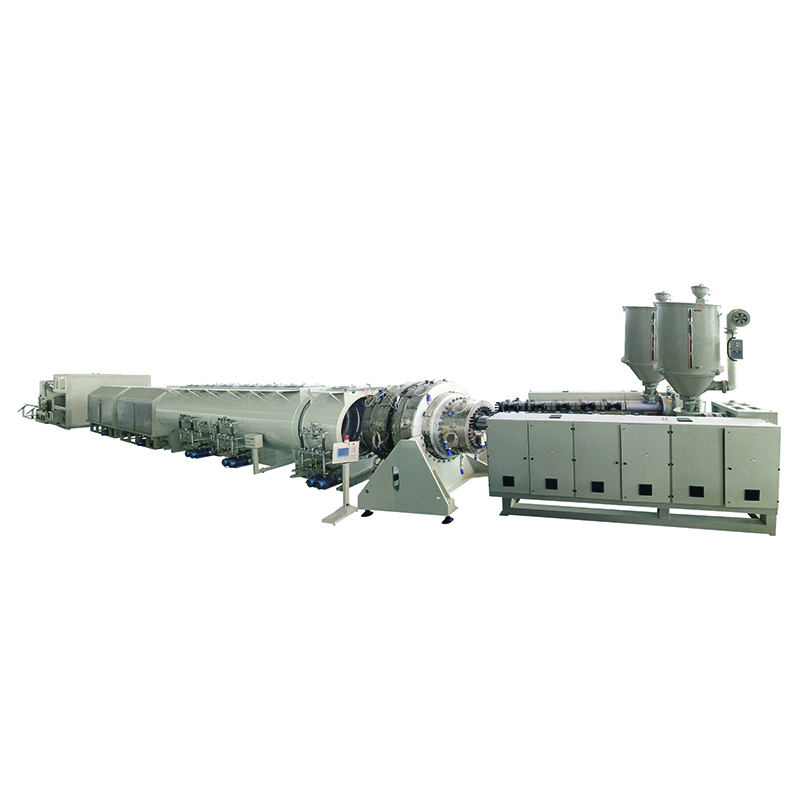

Big Discount Electric Pipe Cutter - LB-Extruder – Langbo

Big Discount Electric Pipe Cutter - LB-Extruder – Langbo Detail:

Extruder is a the core of the whole production line. In the production process, the extruder plays the transporting and plasticizing function. Through feeder, the powder pulling into the screw and barrel part, it is heated, mixed and extruded into definite product. A good extrude will ensure the consistent production and saving more energy in the continuous extrusion.

Price factor: Single screw extruder is cheaper and simpler inner structure.

Plasticizing factor: The single screw extruder is more suitable for extrusion and processing of granular materials. It has little shear degradation of the polymer but long residence time of the material in the extruder.

Processing capacity and energy consumption: Single screw extruder has lower extruder output, extrusion speed, energy consumption and per unit of output.

Operability: Single screw extruder is easy manipulation and simple process control.

Common materials: PE PPR

Price factor: Twin screw extruder is more expensive and has complicated inner structure.

Plasticizing factor: The twin screw extruder has good mixing and plasticizing ability, short residence time of material in the extruder. It is more suitable for powder processing.

Processing capacity and energy consumption: Twin screw extruder has better extruder output, extrusion speed, energy consumption and per unit of output.

Operability: Twin screw extruder is difficult manipulation and complex process control.

Common materials: PVC

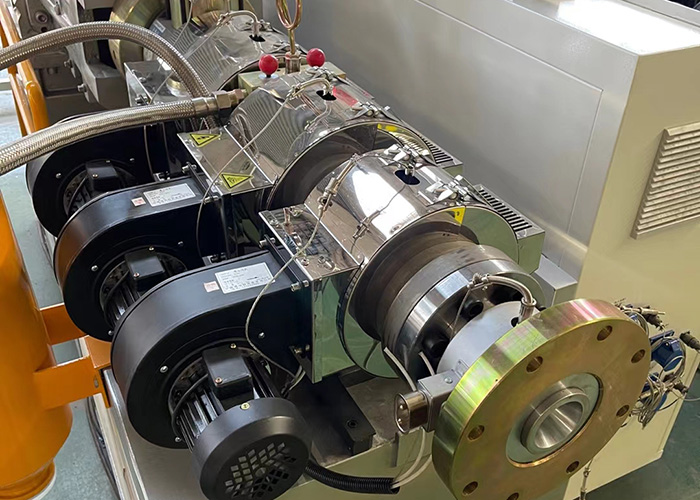

➢ Gearbox

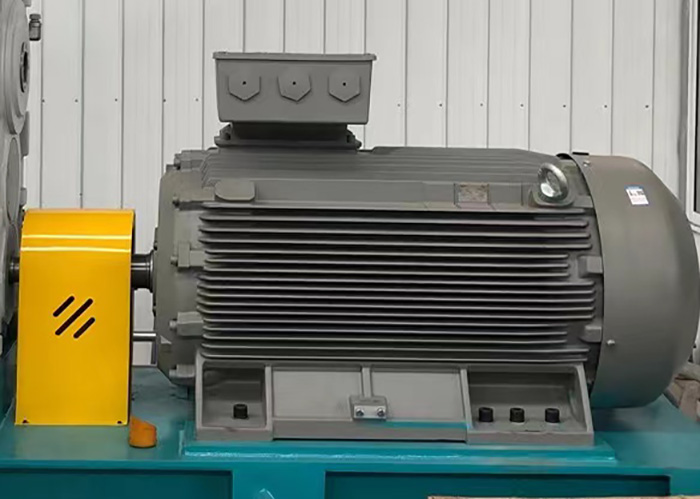

Extruder features ABB/Siemens motor&drive.

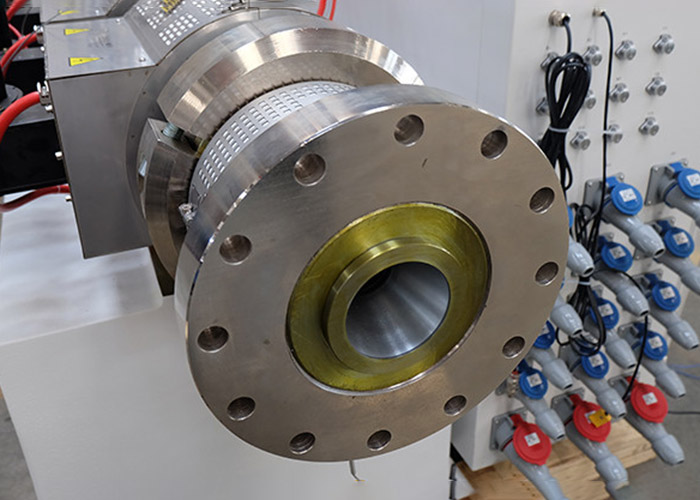

➢ Screw&barrel

Our extruder utilize the high quality screw& barrel.

➢ HMI/P: C

Our extruder has a 12 inch HMI comprised of components from Siemens/Omron.

➢ Electronics

Our Extruders offer Siemens/Schneider Electronics.

Conical twin screw extruder

Details of the second stage extruder

Flange surface by nickel-coating treatment

Integrated vertical type gearbox

Motor power

Overview Conical twin screw extruder

Product detail pictures:

Related Product Guide:

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Big Discount Electric Pipe Cutter - LB-Extruder – Langbo, The product will supply to all over the world, such as: Nairobi, Orlando, Saudi Arabia, What is good price? We provide customers with factory price. In the premise of good quality, efficiency will have to be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products and solutions in time. Sincerely hope we could have long term business relationship.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.