Project Detail

Location: Tunisia

Product: 110mm PVC Pipe Extrusion Line with Mixer Combination and Belling Machine

Highlights

Wide range of product diameter

Tailored solution

High Automation for few labor requirement

Easy operation for less staff training

Tailored Solution

1. Mixer Combination

For same kind of PVC material, the mixing process is necessary. During the mixing the PVC powder will be mixed with additives. Heating and cooling mixing will be automatic executive. After Mixing the material has to be stored for a certain time. And then the mixture will be conveyed into extruder. The whole mixing process will be automatic executive after parameter setting.

2. Parameter indicator

According to our experience on extrusion and operation, operator can monitor the extrusion process and operate the haul-off and cutting machine. Compared with touch screen HMI (Human Machine Interface), the indicator panel can do most of operation and save the cost.

3. Laser Printer

Instead of Ink printer, laser printer is nowadays widely used because of its reliable work and low maintenance cost

4. Double Oven Belling machine

For belling machine, we applied two heating ovens for rapid belling process. In the belling station the pipe end is already hot and can be shaped immediately. The shaping quality and productivity both will achieve the best performance.

Reference case

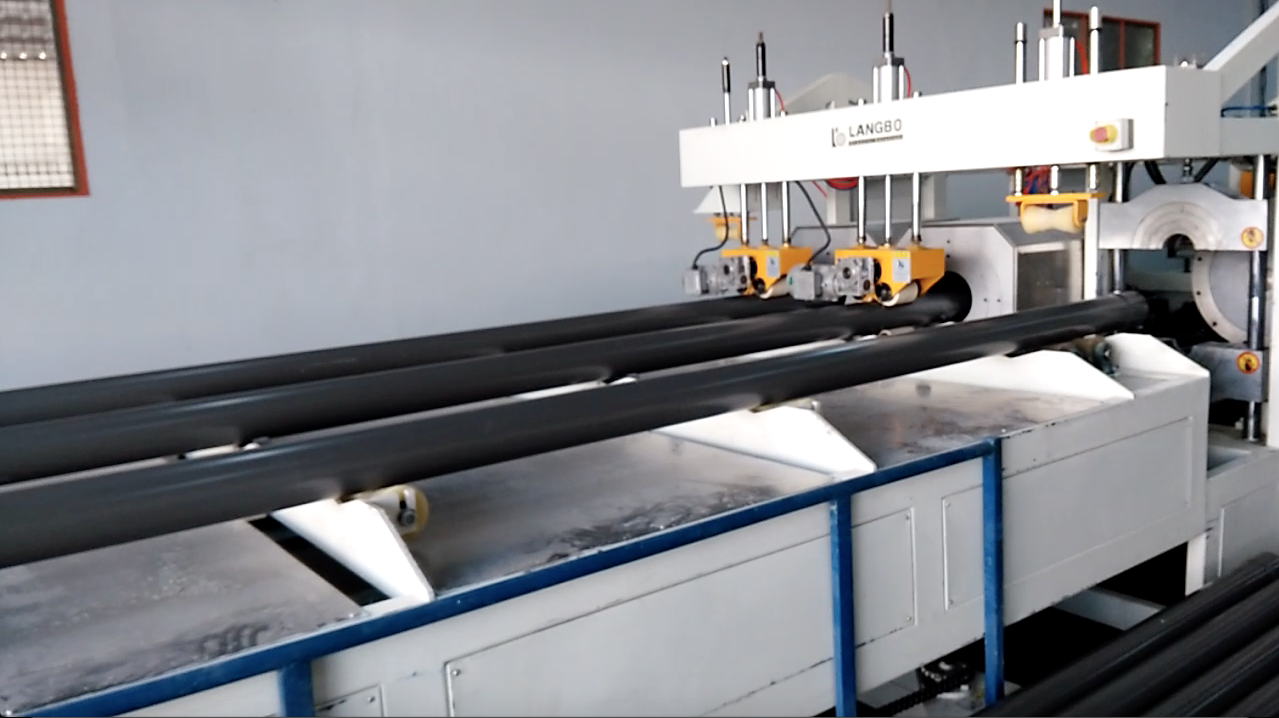

Double strand Extrusion Line

PVC Large Diameter Pipe Extrusion Line

Post time: Mar-23-2023