Project Detail

Location: China

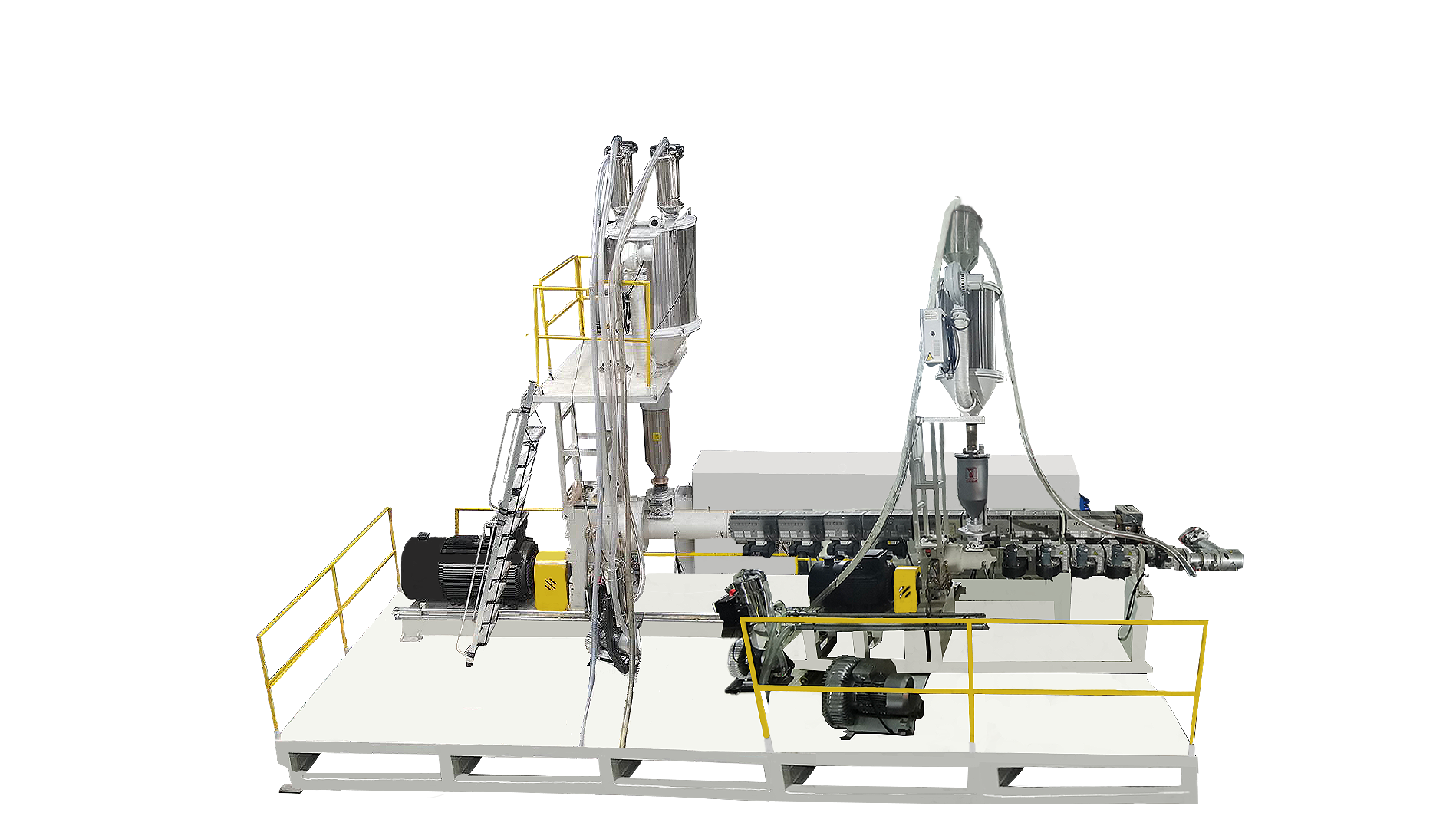

Product: PE Large Diameter Pipe Extrusion Line with Gravimetric Dosing System

Highlights

permanent magnet synchronize motor for energy saving

Energy saving by vacuum control system

Automatic control system

Tailored specification design

High standard manufacture and details for better operation and maintenance

Co-extrusion for high extrusion volume

Tailored Solution

• Long service time design

By model selection of driving motor and screws, we consider the long-term production condition and choose a less wear running matching and anti-wear treatment for barrel and screw. The design concept can guarantee at least 1-year wear resistance with 24 hours running per day.

• Backup-Pumps

In each stage of calibration tank, we prepare one backup water pump and one backup vacuum pump. If one pump is defect, the backup pump works automatically, operators can check the situation and the line runs as usual.

• AC Drive controlled vacuum condition

All vacuum pumps run based on the pressure condition inside of the tanks. Vacuum pumps run hard when the vacuum condition not enough. AC Drives control the pumps and keep the constant vacuum situation in energy efficiency way

• Platform for safety and easy operation

Two extruders are set on one platform. The large pipe extrusion causes a high center line. With a big platform, operator can adjust the two extruders easily safety. It cost more but man can benefit in aspect of daily operation and maintenance in the whole life cycle of the line.

Reference Case

HDPE pipe extrusion line

HDPE water supply pipe extrusion line

Post time: Mar-23-2023