Chinese Professional Water Supply Pipe Production Line - LB-HDPE Pipe Production Line – Langbo

Chinese Professional Water Supply Pipe Production Line - LB-HDPE Pipe Production Line – Langbo Detail:

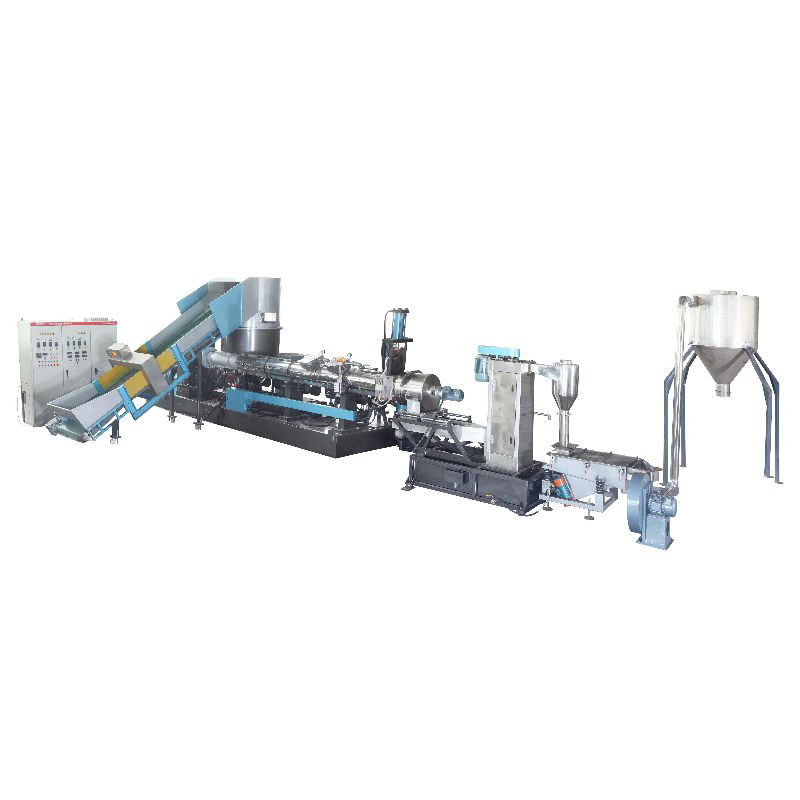

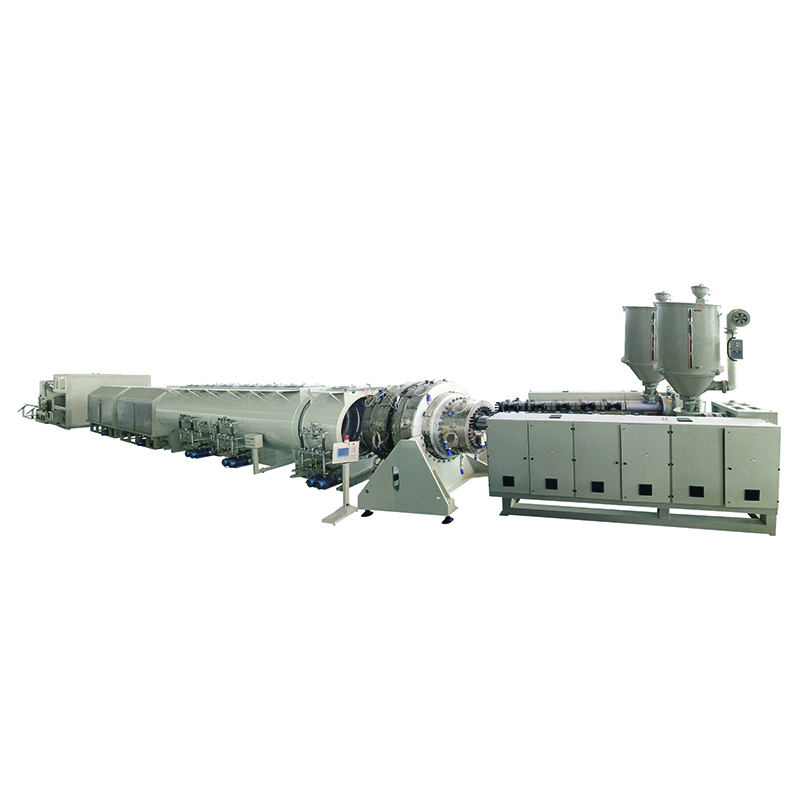

PE particles—material feeder—single screw extruder—mould and calibrator—vacuum forming machine—two-staged spraying cooling machine—haul-off machine—rapid cutter/Planetary cutter—stacker.

| Model | LB63 | LB110 | LB250 | LB315 | LB630 | LB800 |

| Pipe Range | 20-63mm | 20-110mm | 75-250mm | 110-315mm | 315-630mm | 500-800mm |

| Screw Model | SJ65 | SJ75 | SJ90 | SJ90 | SJ120 | SJ120+SJ90 |

| Motor power | 37KW | 55KW | 90KW | 160KW | 280KW | 280KW+160KW |

| Output | 100kg | 150kg | 220kg | 400kg | 700kg | 1000kg |

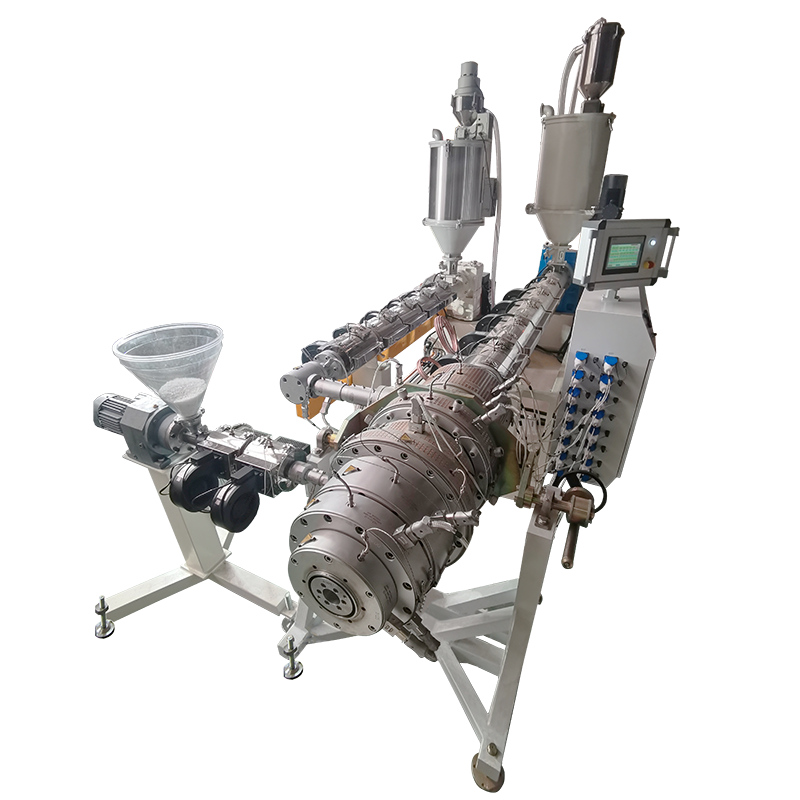

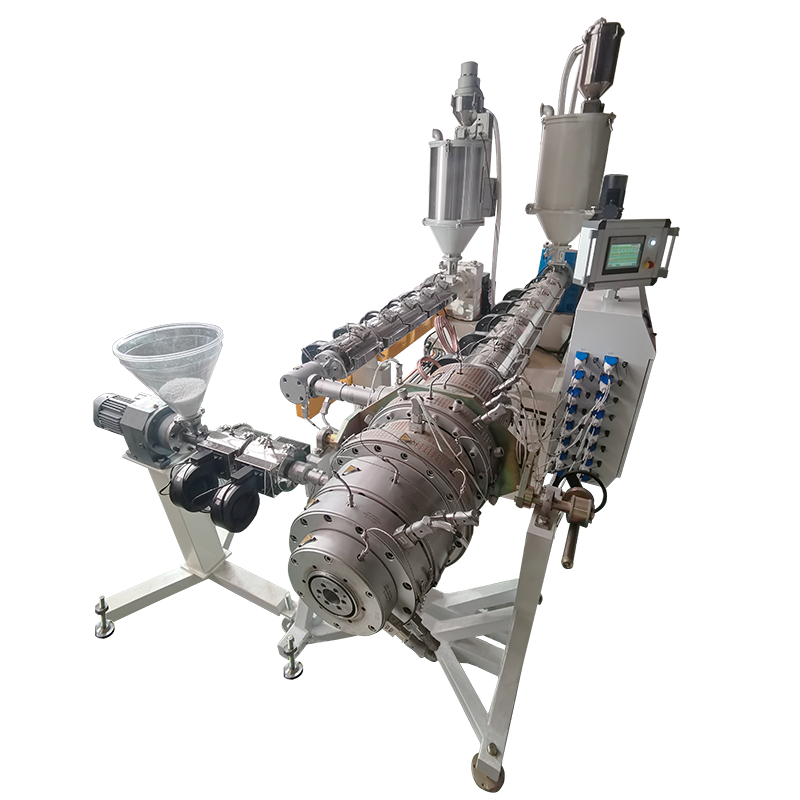

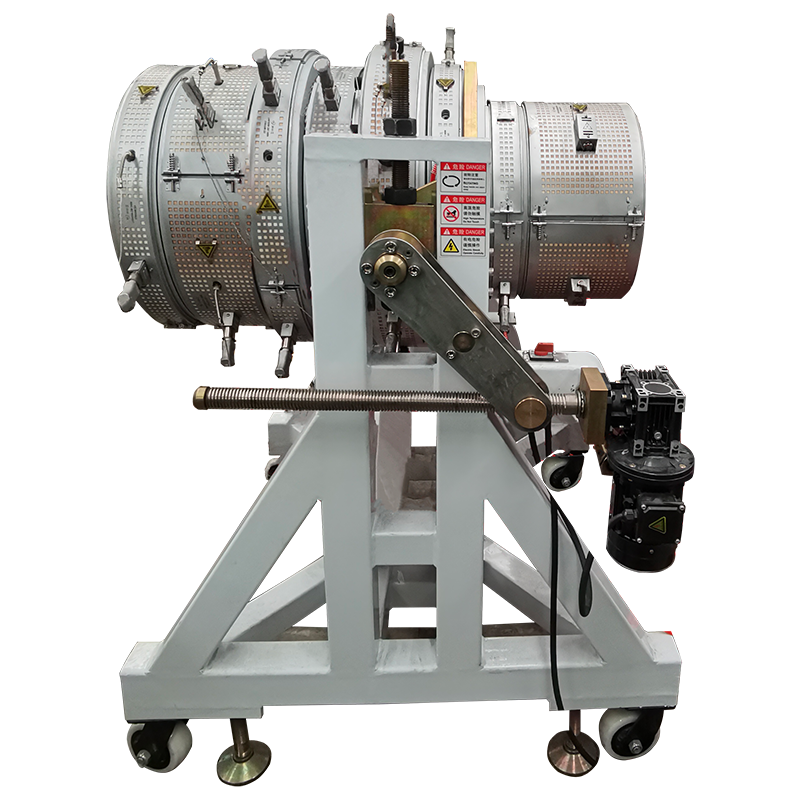

Single screw extruder machine

The extruder are crafted with top brand components to ensure production stability, efficiency and machine durability. Our extruder allocate international standard single screw and barrel. The screw has strong rigidity ensuring long service life and distinguished plasticizing effect.

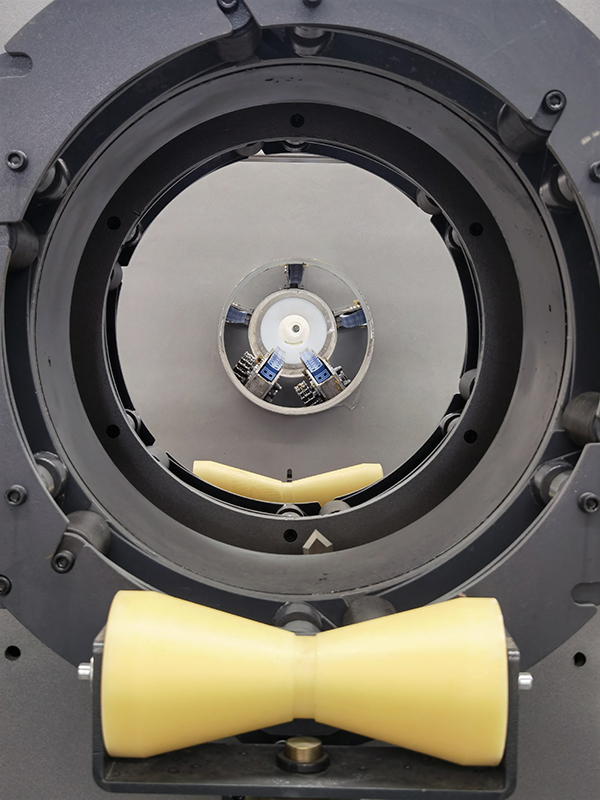

Mould

The mould has spacious flow channel design to guarantee high extrusion capacity and good melting effect.

It is made and inspected by the experienced manufacturer. The optimized temperature control and flow channel design ensures precise melt temperature control.

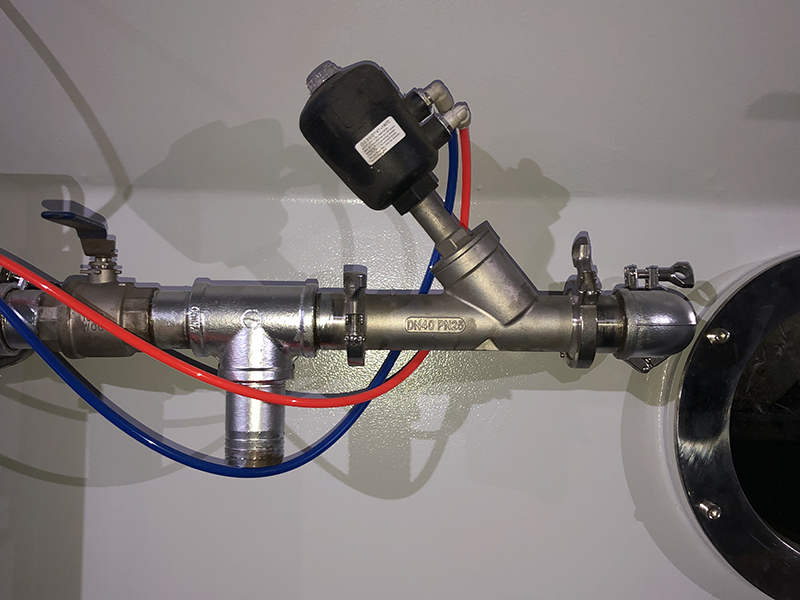

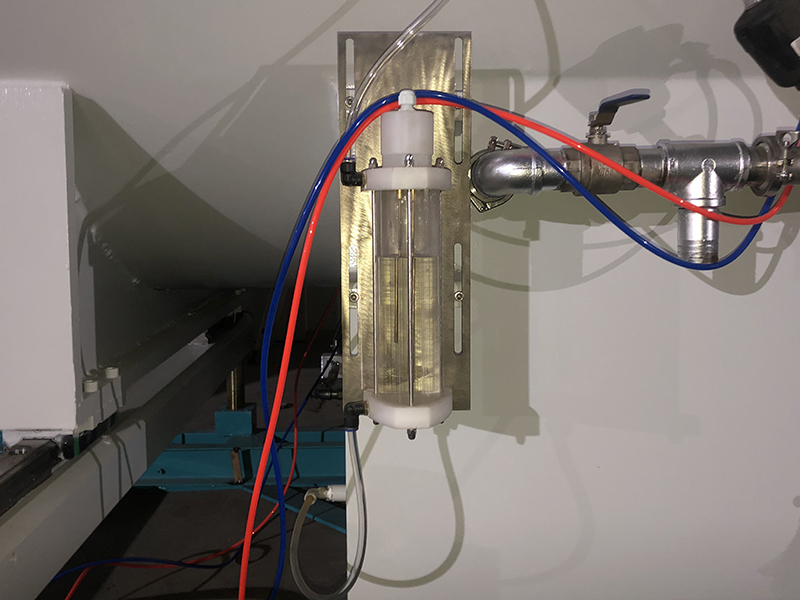

Vacuum and cooling tank

The vacuum calibration tank adopts stainless 304 steel. The excellent vacuum system ensures precise sizing for pipes. The holder in first step of the vacuum calibration tank guarantees the pipe shaped and provides extra power for the pipes moving on.

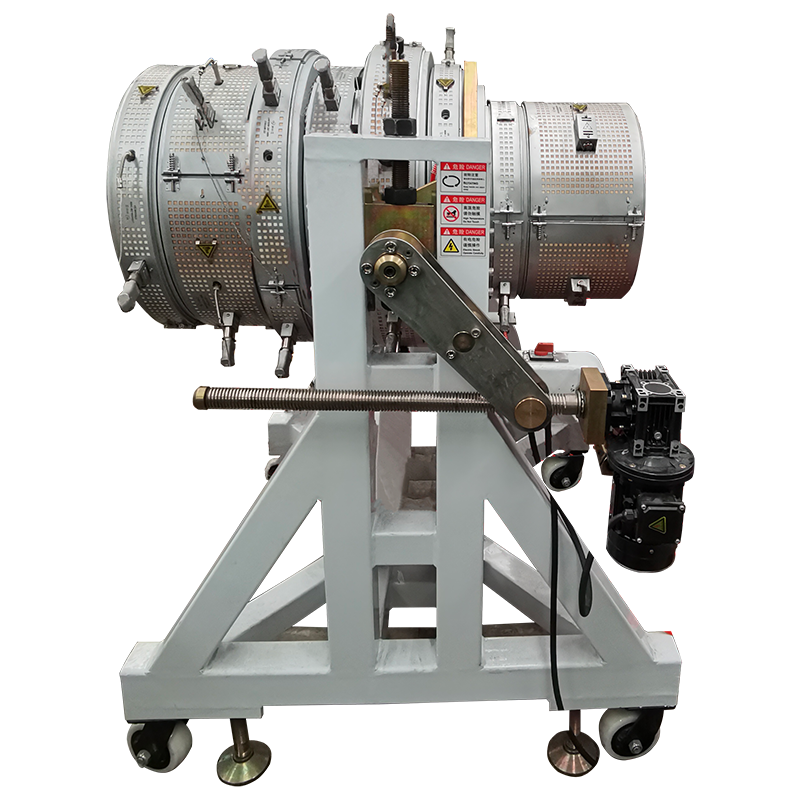

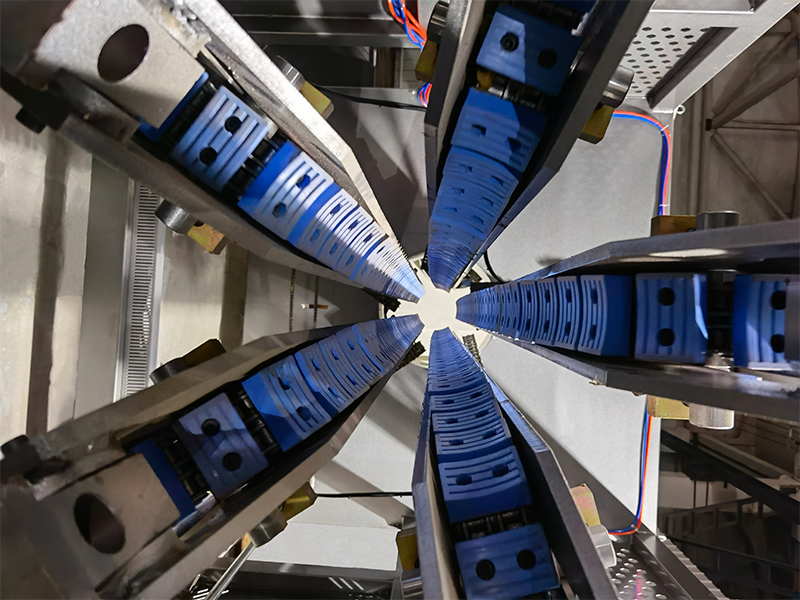

Haul-off Unit

The ten caterpillar on the haul-off machine ensures produced pipe running stably and steady. utilize a unique mechanism to prevent pipe ovality while our unique belt design assures proper pulling without slippage.

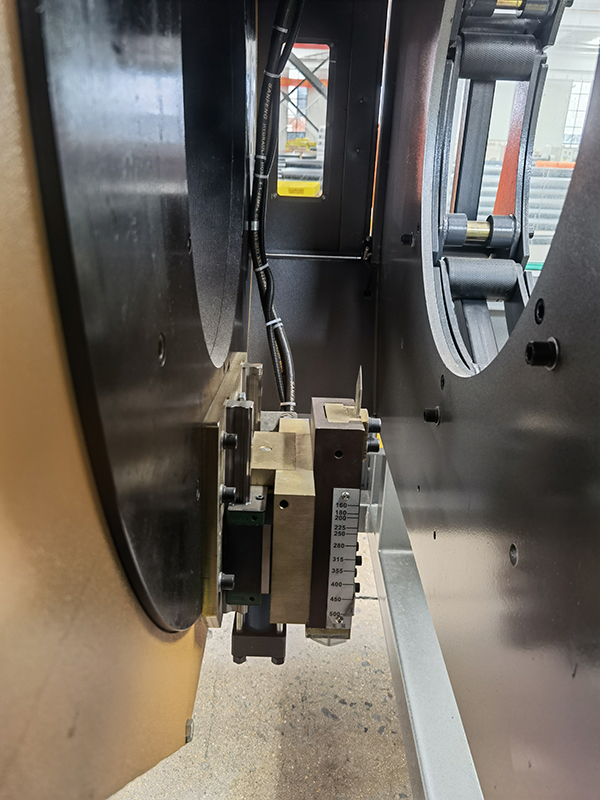

Cutting Unit

We offers two cutting methods including rapid cutter and planetary cutter. In accordance to the

produced pipe material, the cutting way can be switched randomly.

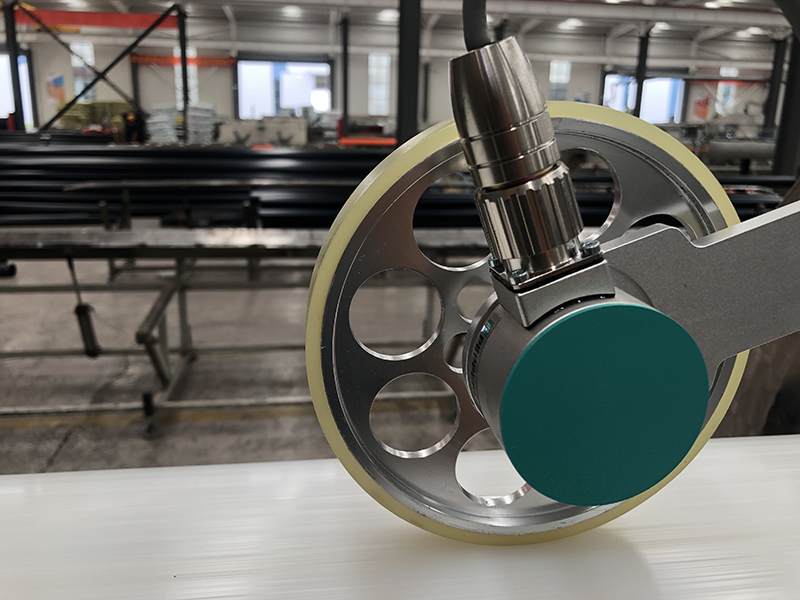

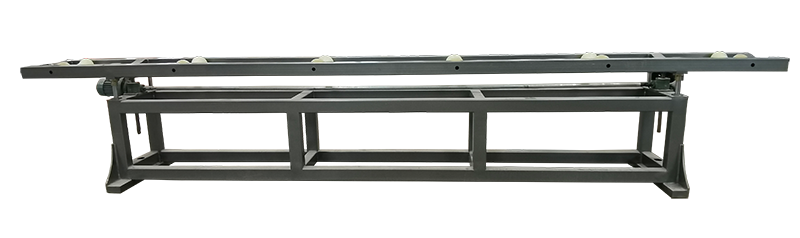

Tipping table

Our Tipping table is made by 304 quality stainless material of iron structure, sturdy structure and heavy load bearing. Our rubber wheel steady hold the pipe product without scratch risk.

Product detail pictures:

Related Product Guide:

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for Chinese Professional Water Supply Pipe Production Line - LB-HDPE Pipe Production Line – Langbo, The product will supply to all over the world, such as: Malta, Guatemala, Atlanta, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are satisfactory reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Problems can be quickly and effectively resolved, it is worth to be trust and working together.