Discountable price Foam Board Cutter - LB-Extruder – Langbo

Discountable price Foam Board Cutter - LB-Extruder – Langbo Detail:

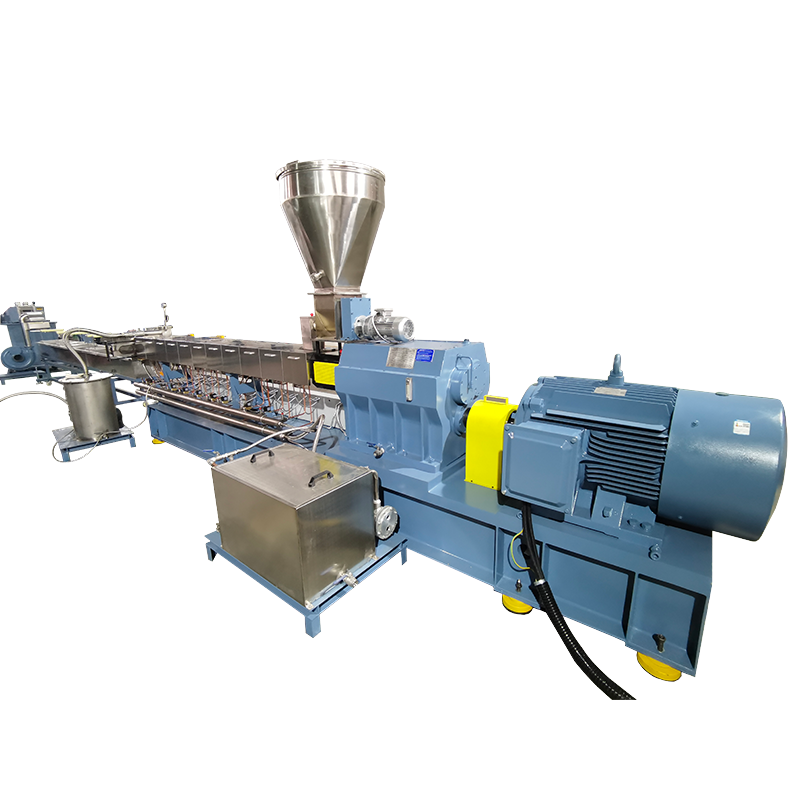

Extruder is a the core of the whole production line. In the production process, the extruder plays the transporting and plasticizing function. Through feeder, the powder pulling into the screw and barrel part, it is heated, mixed and extruded into definite product. A good extrude will ensure the consistent production and saving more energy in the continuous extrusion.

Price factor: Single screw extruder is cheaper and simpler inner structure.

Plasticizing factor: The single screw extruder is more suitable for extrusion and processing of granular materials. It has little shear degradation of the polymer but long residence time of the material in the extruder.

Processing capacity and energy consumption: Single screw extruder has lower extruder output, extrusion speed, energy consumption and per unit of output.

Operability: Single screw extruder is easy manipulation and simple process control.

Common materials: PE PPR

Price factor: Twin screw extruder is more expensive and has complicated inner structure.

Plasticizing factor: The twin screw extruder has good mixing and plasticizing ability, short residence time of material in the extruder. It is more suitable for powder processing.

Processing capacity and energy consumption: Twin screw extruder has better extruder output, extrusion speed, energy consumption and per unit of output.

Operability: Twin screw extruder is difficult manipulation and complex process control.

Common materials: PVC

➢ Gearbox

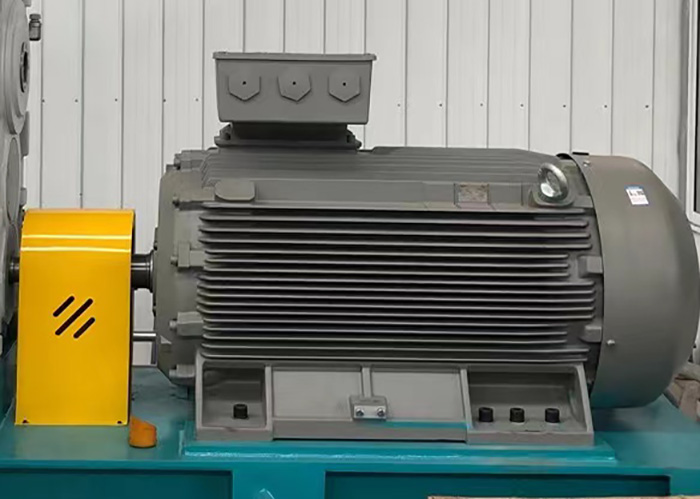

Extruder features ABB/Siemens motor&drive.

➢ Screw&barrel

Our extruder utilize the high quality screw& barrel.

➢ HMI/P: C

Our extruder has a 12 inch HMI comprised of components from Siemens/Omron.

➢ Electronics

Our Extruders offer Siemens/Schneider Electronics.

Conical twin screw extruder

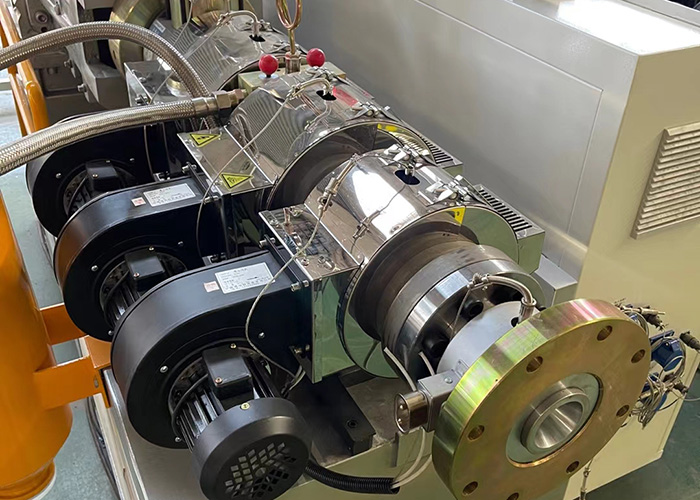

Details of the second stage extruder

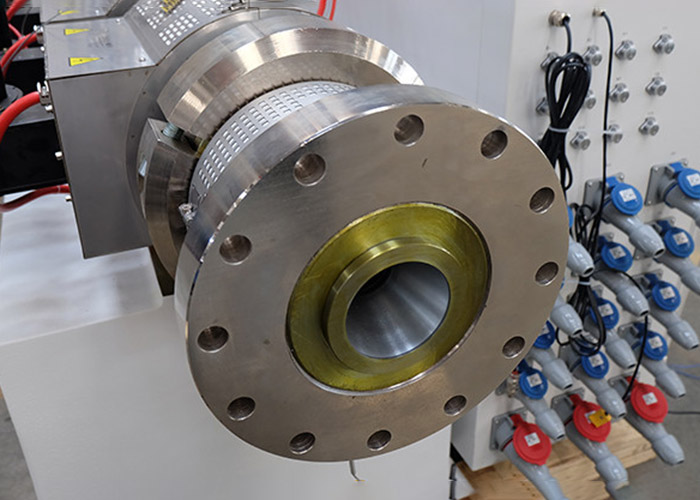

Flange surface by nickel-coating treatment

Integrated vertical type gearbox

Motor power

Overview Conical twin screw extruder

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for Discountable price Foam Board Cutter - LB-Extruder – Langbo, The product will supply to all over the world, such as: Zambia, Kenya, South Korea, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products and solutions at the lower prices to different markets. Our company has already set up a experienced, creative and responsible team to develop clients with the multi-win principle.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!