Factory wholesale Plastic Washing Recycling Line - LB- PP/PE Film/Bag/Rigid scraps Washing& Recycling Line – Langbo

Factory wholesale Plastic Washing Recycling Line - LB- PP/PE Film/Bag/Rigid scraps Washing& Recycling Line – Langbo Detail:

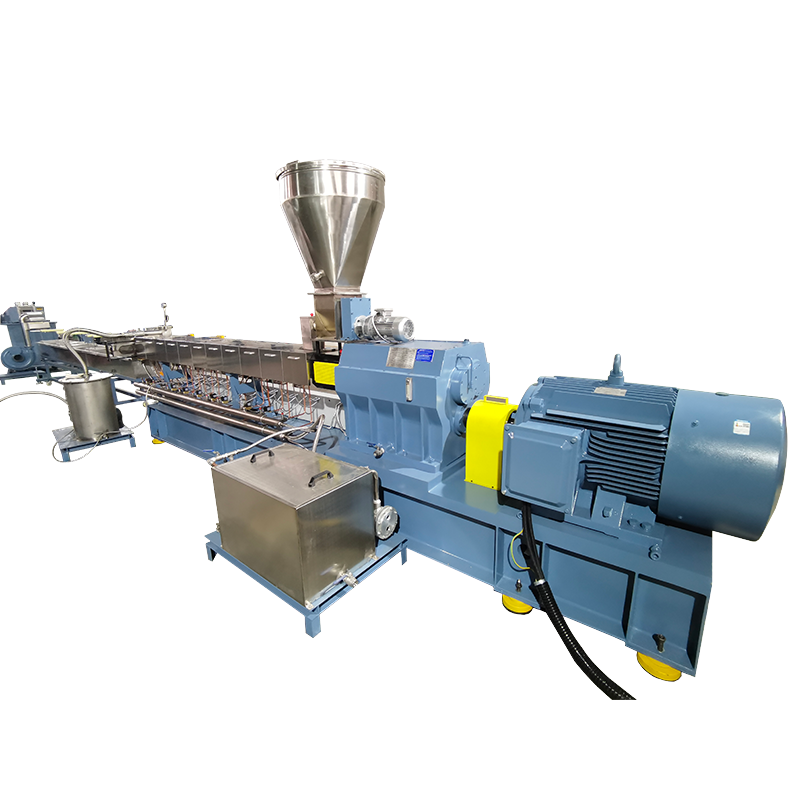

LB Machinery PP/PE Film/Bag/Rigid scraps Washing& Recycling Line

PP/PE Film and bag is pervasive in our life. Meanwhile, it is an important part in the plastic recycling and processing industry. Through crushing the wasted film/Bag, we obtain small particle scrapes. After cold and hot water washing, we acquire clean and soft flakes or rigid scraps. Those clean scrapes is used for the next application. The process and re-sale is economical and eco-friendly which is a promising business.

Langbo Machinery has over 12 years experience in the LB Machinery PP/PE Film/Bag/Rigid scraps Washing& Recycling Line. We offer the recycling line to industry worldwide, and our recycling program is designed to reduce operating costs and obtain quality PET flakes.

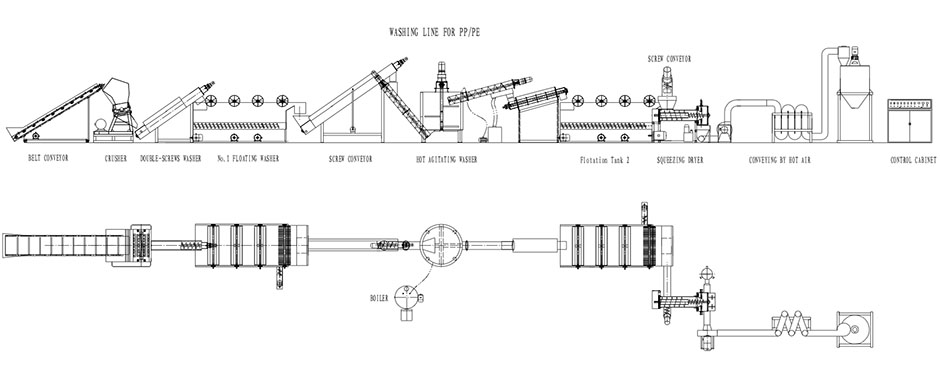

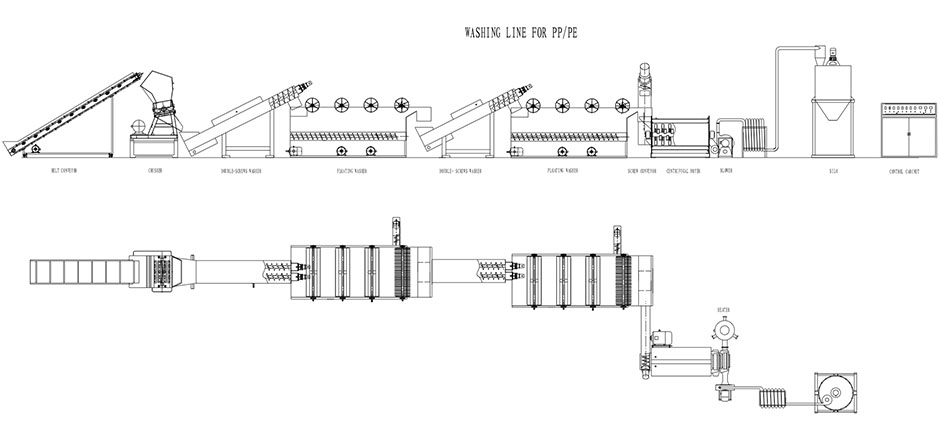

The processing procedure of the complete washing line consists of conveying – crushing – floating washer with cold water – agitating washer with hot water – floating washer with cold water – centrifugal drying/squeezing drying – collection.

➢ Belt conveyor

➢ Shredder&crusher

➢ Hot Washer

➢ Centrifugal Dryer

➢ Cold Washer

➢ Floating Washer

➢ Collection

➢ Applicable material: PP, HDPE, LDPE, LLDPE, etc..

➢ Materials shape: woven bag, printed films, agricultural film, raffia and rigid scraps.

The production capacity can be 300kg/hr, 500kg/hr, 1000kg/hr.

Note: Depending on material shape, some units involved in complete line will be changed and available.

Complete washing & recycling line

Crusher recycling

Double screw friction washer recycling

Floating cold washer recycling

Friction and hot washing

Product detail pictures:

Related Product Guide:

We stick with the theory of quality first, company first, steady improvement and innovation to satisfy the customers for the management and zero defect, zero complaints as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for Factory wholesale Plastic Washing Recycling Line - LB- PP/PE Film/Bag/Rigid scraps Washing& Recycling Line – Langbo, The product will supply to all over the world, such as: Barcelona, Norwegian, Cyprus, To work with an excellent products manufacturer, our company is your nice choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!