Factory wholesale Wall Panel Making Machine - LB-PVC Wall Panel Extrusion Line – Langbo

Factory wholesale Wall Panel Making Machine - LB-PVC Wall Panel Extrusion Line – Langbo Detail:

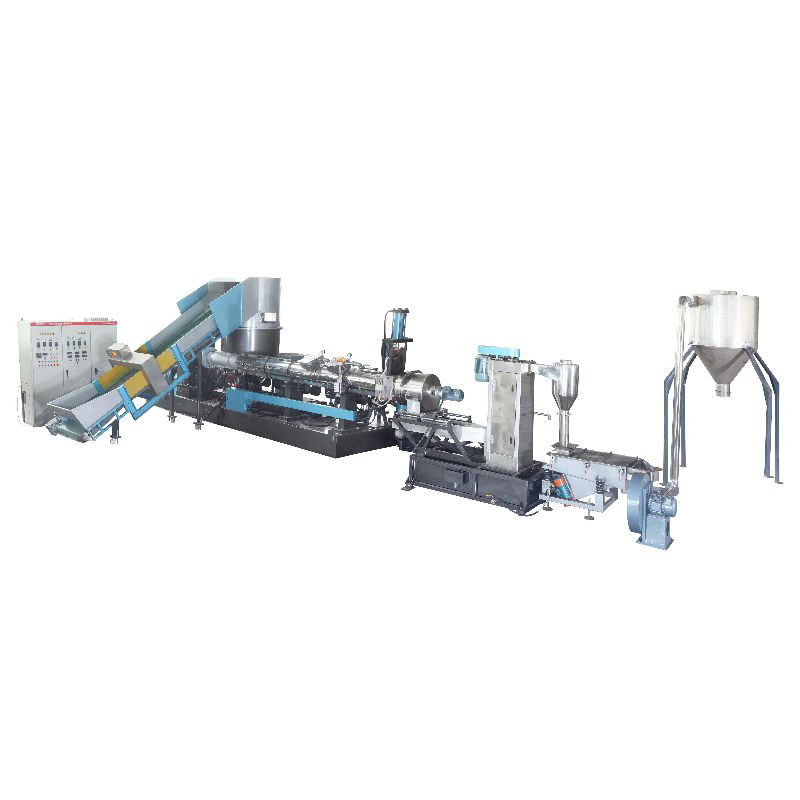

LB Machinery PVC Wall Panel Extrusion Line

LB Machinery offers complete extrusion line for pvc wall panel tailored to the drawings of customers. Our wall panel extrusion mould is manufactured and regulated by experienced expert conformed to national standard. Our wide wall panel caterpillars hauling-off allocates rocket arm providing sufficient driving force and moving speed. The saw cutter is controlled by PLC humanized machine and easier operation. We offer top brand machine components ensuring the durability and productivity.

➢ Mixer

PVC resin and other additives can be bought and mixed together by customers themselves according to formula and the application. For the wall panel production(PVC profile), high quality mixer is necessary and essential.

➢ Conical twin screw extruder machine

Due to the heating sensitivity feature of PVC, we adopt high-quality conical twin screw. In the processing, the rotation and plasticizing is temper and precision.

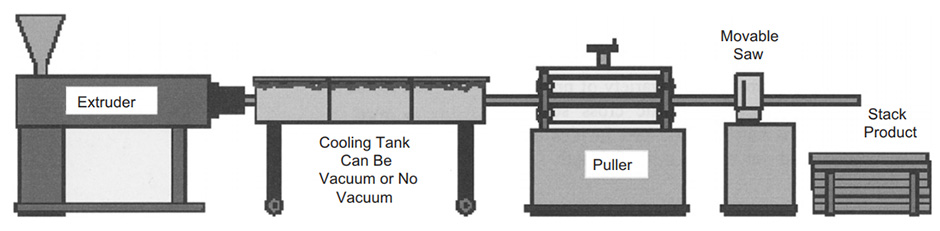

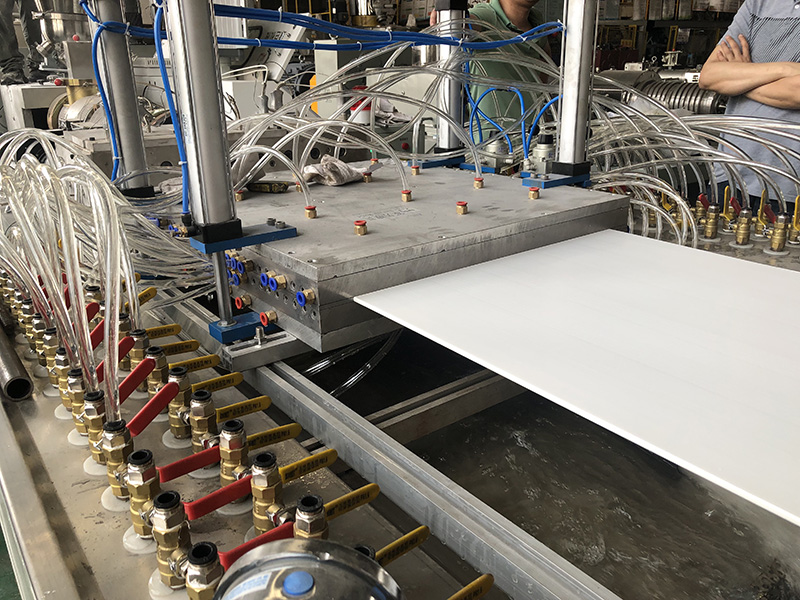

➢ Calibration table

We offer 8-12m calibration table ensuring sufficient cooling and solidification. Twelve sprinklers are continuously watering on the wall panel profile.

➢ Haul off (puller) machine

Our wide wall panel caterpillars hauling-off allocates rocket arm providing sufficient driving force and moving speed.

➢ Cutter machine

The saw cutter is controlled by PLC humanized machine and easier operation.

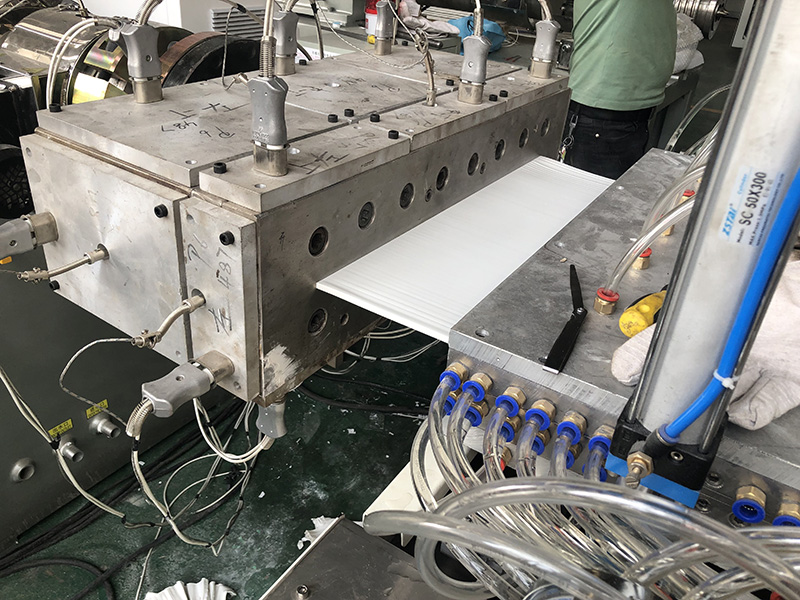

➢ Extrusion coating and lamination

The extrusion lamination machine is used to coating on the wall panel profile. After processing, the panel will have good-looking and wear-resisting consistent to different application.

Cutting unit

Haul-off unit

Laminator

Profile mould

Profile vacuum tank

Wide board product

Why choose LB machinery?

➢ We focus on details and reliable production technology, the machine design are based on plant resource condition and individual requirements.

➢ Our R&D department is dedicated to seeking for much better extrusion way in order to save energy and get maximum efficiency.

➢ The service term holding the the original intention of being responsible for each customers provide real-time report from making order to delivering machines.

| Model | LB-100 | LB-300 | LB-500 |

| Width of Profile (mm) | 100 | 300 | 500 |

| Screw Model | 55/110 | 65/132 | 80/156 |

| Capacity(kg/h) | 150 | 250 | 400 |

Product detail pictures:

Related Product Guide:

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for Factory wholesale Wall Panel Making Machine - LB-PVC Wall Panel Extrusion Line – Langbo, The product will supply to all over the world, such as: Venezuela, Swansea, Gambia, Nowadays our products sell all over the domestic and abroad thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!