LB-Co-extrusion double layer wpc profile extrusion line

Raw material +wood power+ additive → mixing → granulating → conical twin-screw extruder → profile extrusion mould → cool molding die → vacuum calibration support →haul-off → cutter → rack → finished product

1> Conical Double screw extruder: SJSZ-65/132

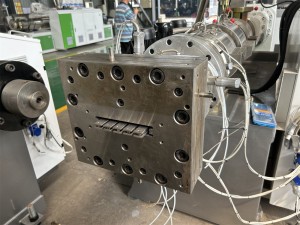

2> WPC PP/PE/PVC windows,doors,fencing, decking,skirting,floor profile mold

3> Vacuum calibrating system

4>Haul off machine

5> Cutting machine

6> Discharge bracket

7> Mixer

8> Embossing machine

| Extruder Model | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 | ||

| Motor power(kw) | 22 | 37 | 55 | 110 | ||

| Product width | 200 | 240 | 300 | 600 | 900 | 1200 |

| Vacuum power | 4kwX1 | 5.5kwX1 | 5.5kwX1 | 5.5kwX2 | 5.5kwX1 7.5kwX1 | 5.5kwX1 7.5kwX1 |

| water pump | 2.2kw | 2.2kw | 4kw | 5kw | 7.5kw | 7.5kw |

| Hauling speed | 0-5m/min | 0-5m/min | 0-5m/min | 0-3m/min | 0-2.5m/min | 0-2.5m/min |

| Capacity (kg/h) | 70kg/h | 110kg/h | 110kg/h | 170kg/h | 300kg/h | 300kg/h |

| Net Weight(kg) | 3000 | 5000 | 6500 | |||

If raw material is PE or PP , you need mix wood powder + PP/PE particles together ,and then put them into pelletizing line , finally get final wood plastic pellets .