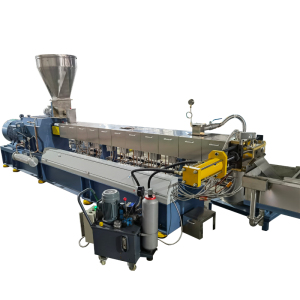

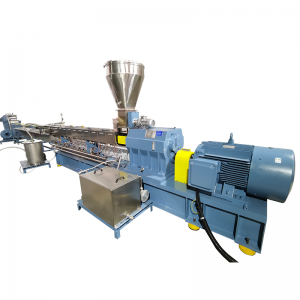

LB-Factory Price Water Slide Cutting Granulating Machine With CE approval

| Model | LBSC-40 | LBSC-50 | LBSC-60 | LBSC-70 | LBSC-80 | LBSC-90 |

| Screw Model | 41/24-80:1 | 52/24-80:1 | 62/24-80:1 | 71/24-80:1 | 81/24-80:1 | 93/24-80:1 |

| Throughput(kg) | 100 | 200 | 350 | 450 | 750 | 1000 |

| Motor Power(kW) | 37 | 75 | 110 | 160 | 250 | 315 |

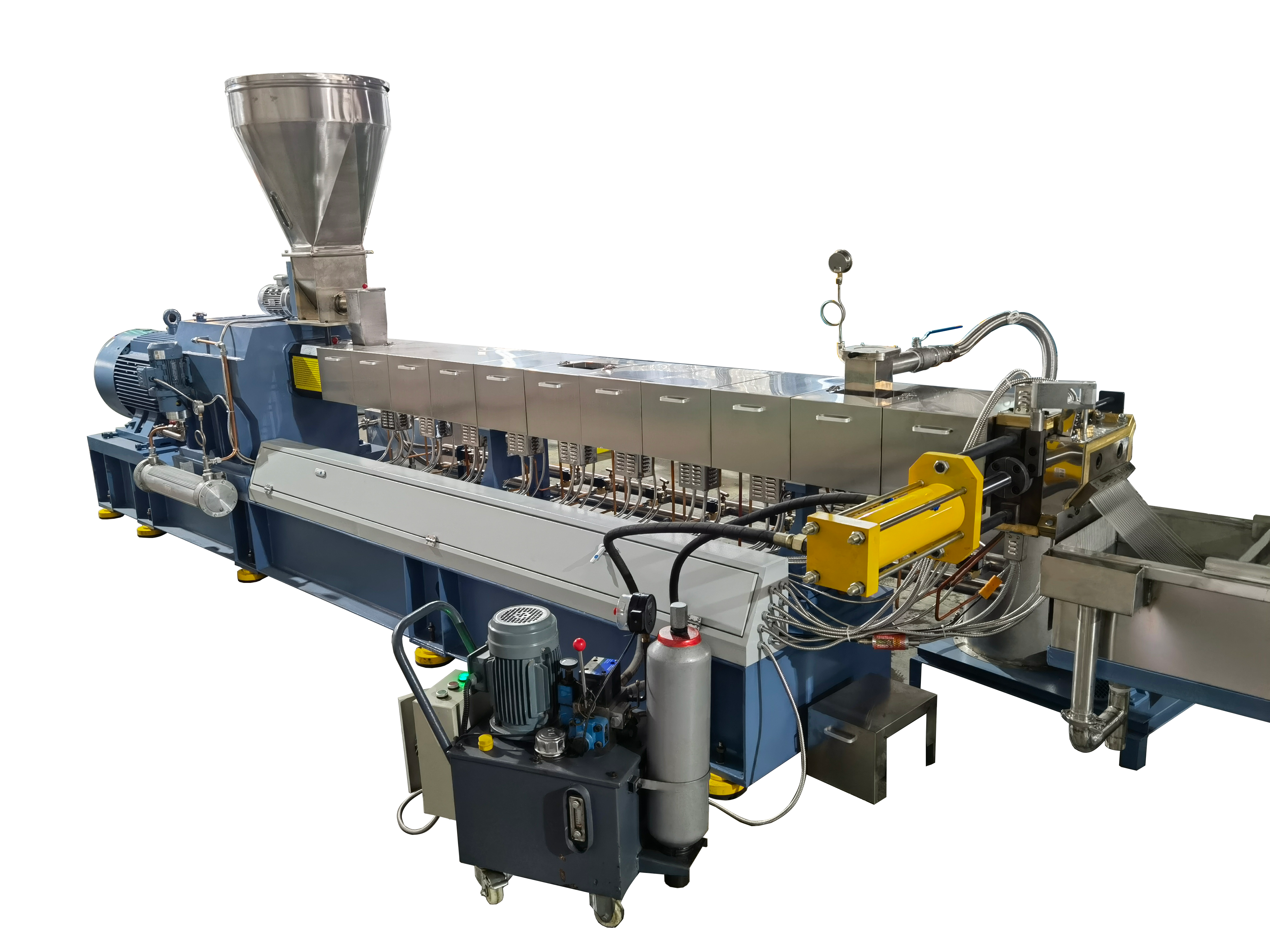

Parallel Twin Screw Extruder

Heavy Load Gearbox for reliable running

High precise screw part for excellent screw building

High quality electrical parts and worldwide famous brand for drive unit

Easy Temperature setting and indication

Degassing section for tailored processing demand

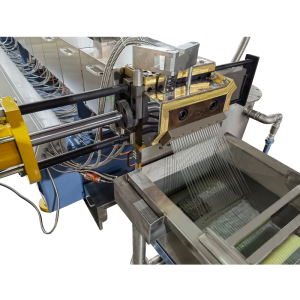

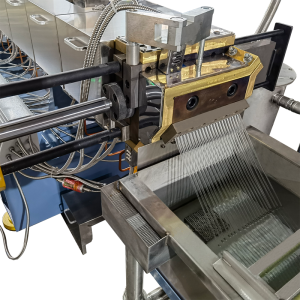

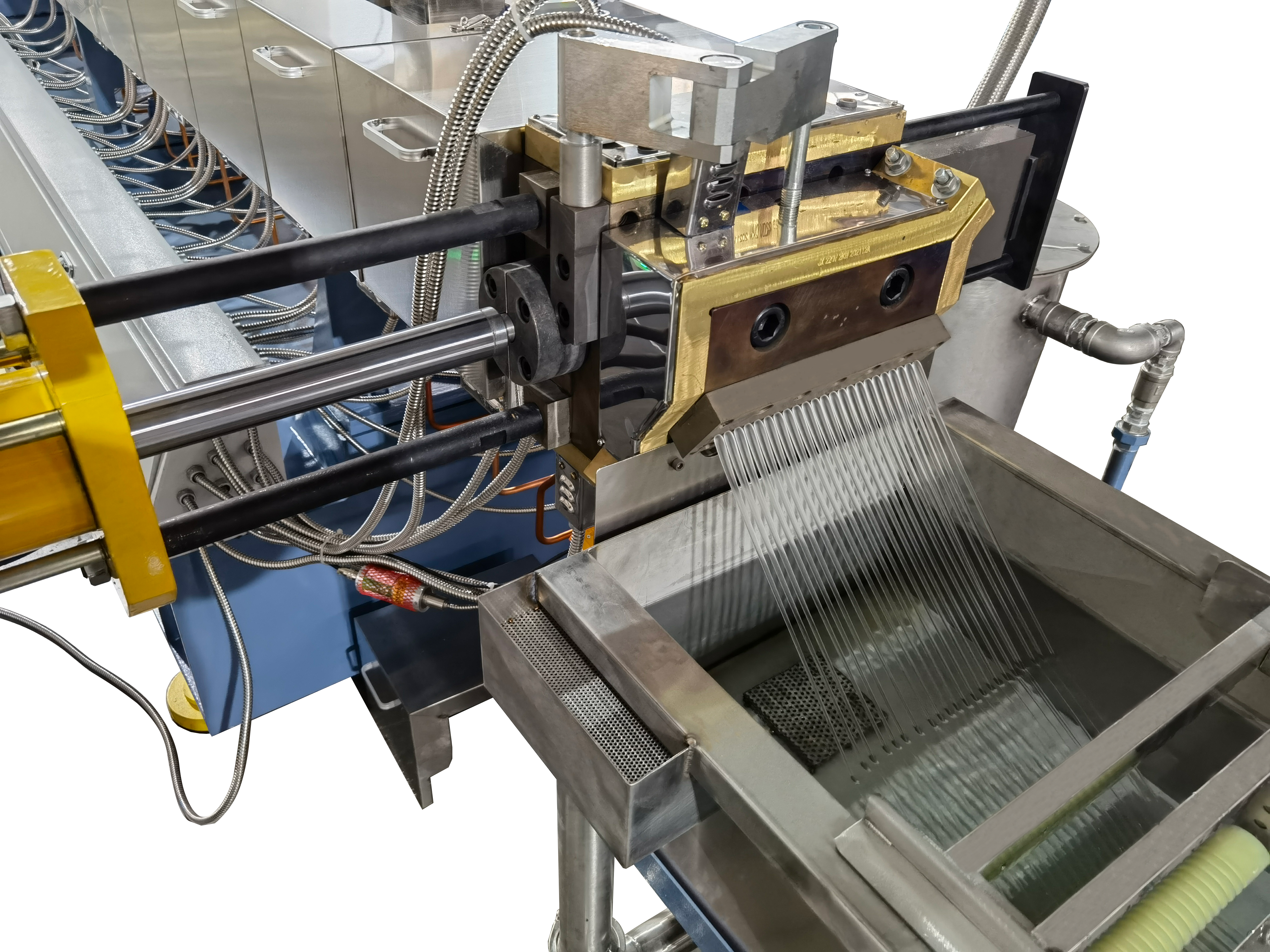

Hydraulic Melt filter Mould

304 Steel screens with tailored mesh size

Hydraulic plate or cylinder filter body available

Bronze heater for high heating efficiency

Water Slid Cooling

Carrying with the advantages of strand cutting like low equipment cost and easy maintenance. The water slide strand cutting has its own advantages such as: better strand broken protection and better cooling efficiency. The water slide is for plastic recycling widely applied.

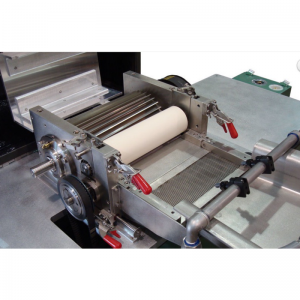

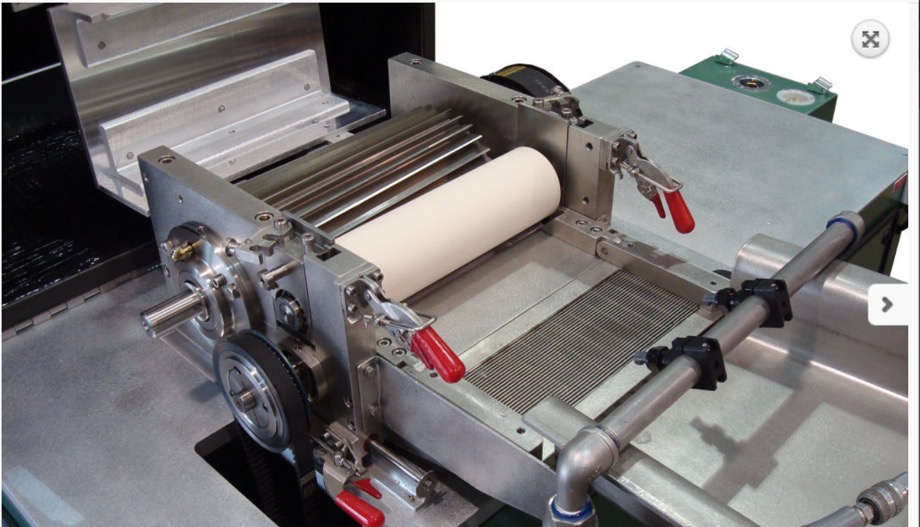

Pelletizer

Pelletizers are completely made of AISI 304 stainless steel. Pelletizing blades and die are made of special alloy steels and coatings according to the type of plastic. By mobile parts, maintenance period is minimized. Speed control for pelletizing blades enables changing granule size during operation.

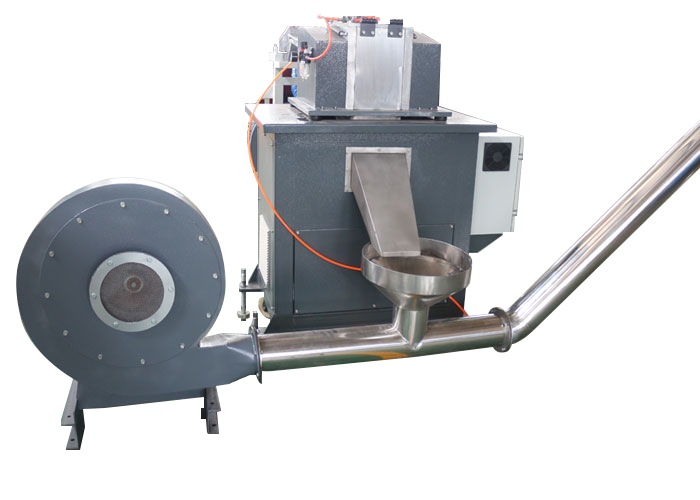

Centrifugal dewatering

It separates the granules and water. The Granules will through centrifugal drying be transported from the bottom to top of dewatering device. During the lifting the moisture will be effectively reduced.

Vibration Sieve

Granules’ size controlled by vibration sieve too small or too big granules will be flited out. The only granules, which fit the size requirement will be transported into storage silo by air.

Air blowing

The vibration sieve is figuring and moving the pellets through constant vibration. If the customers just want to get the pellets no matter shape or size. The air blowing can be adopted after the centrifugal dewatering machine.

Storage Silo

Final Granules will be stored in silo. Based on demand the on-line monitoring and weighting system will can be applied.