LB-Manual and automatic PVC pipe socket making machine

Pipe range:Φ 315-630mm(outer diameter)

Belling type:R type & U type

Used oil label:No. 40/hydraulic oil

Brand Name: Langbo

highest temperature in heater: 280 centigrade

Dimension(L*W*D)8615x3125x2500mm

Pipe length: 3-6m

Color: Customized

Condition: New

Warranty of core components:1 year

Place of Origin:Zhangjiagang Jiangsu,China

Quantity of heater: 2

Gas pressure: Gas pressure 0.6~0.8Mpa

Water pressure:0.2~0.3Mpa

Center height: 900mm± 50mm

Type: PVC belling machine

After Warranty Service:Engineer to site support, spare parts, online video support.

|

MODEL |

Pipe diameter |

Belling way |

Cooling way |

Socket shape |

Control way |

|

LB-40 |

16-40 (double) |

Pneumatic |

Blowing air |

“U” |

Automatic/Manual |

|

LB-200 |

50 -200 |

Hydraulic |

Water |

“U”/“R”/”Rectangular” |

Automatic/Manual |

|

LB-250 |

50 -250 |

Hydraulic |

Water |

“U”/“R”/”Rectangular” |

Automatic/Manual |

|

LB-400 |

160-400 |

Hydraulic |

Water |

“U”/“R”/”Rectangular” |

Automatic/Manual |

|

LB-500 |

200-500 |

Hydraulic |

Water |

“U”/“R”/”Rectangular” |

Automatic/Manual |

|

LB-630 |

315-630 |

Hydraulic |

Water |

“U”/“R”/”Rectangular” |

Automat |

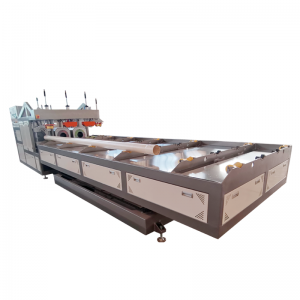

This line provides manual and automatic PVC pipe socket making including “U” or “R” sockets. Mostly it is following the extrusion line, matching with slotting or screwing machines. It can also work separately. Our belling machine has two heating ovens. Before belling, the pipes will be heated in the heating oven. And when the pipes sending to belling, another pipe will be sent to heating. Therefore, the line has high output and fast working speed.

The key technology on the belling machine is the precision of the sockets after the belling machine. Especially, the socket belled will be applied for threading connection as your requirements.

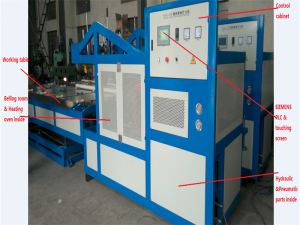

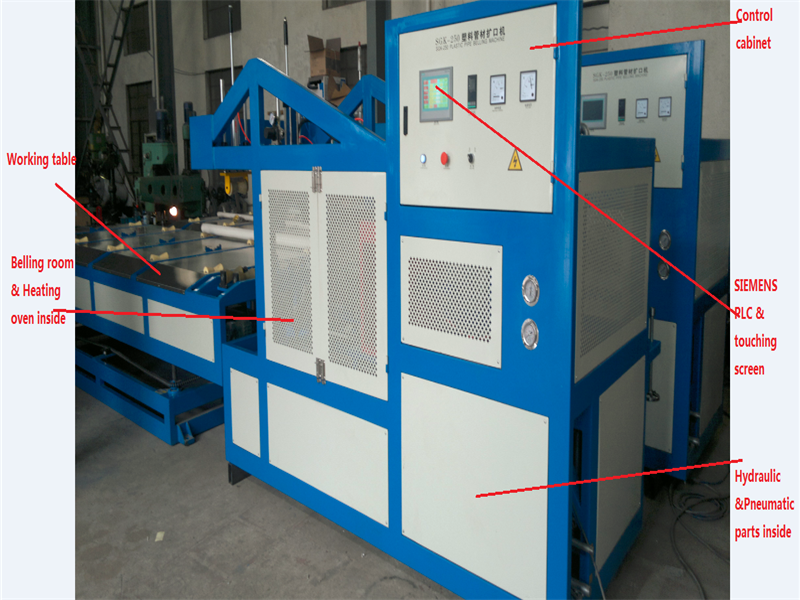

• Our belling machine includes control cabinet, SIEMENS PLC& touching screen,Hydraulic& Pneumatic parts, Working table, Belling room& Heating oven.

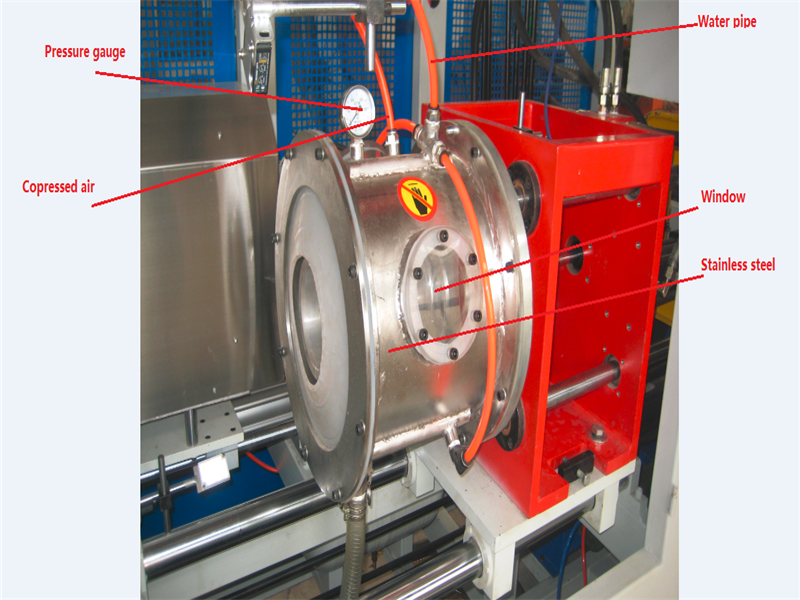

• To ensure the precision of the sockets belled, we adapted the belling processing will be done inside the pressure container and cooling was done by water spayed as following picture:

• We employed two Heating Ovens to improve the production capacity. One pipe will be heated when another pipe was under the processing of belling. Comparing to the belling machine as your picture, the production capacity will be 2 times as yours.

The machines in LANGBO Machinery are qualified with CE and ISO certificates.