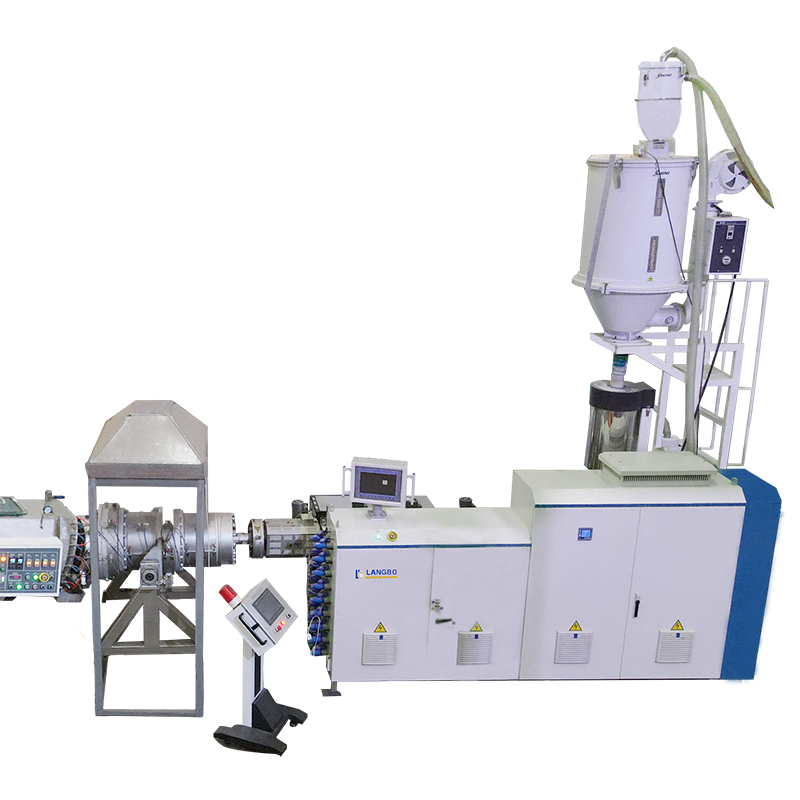

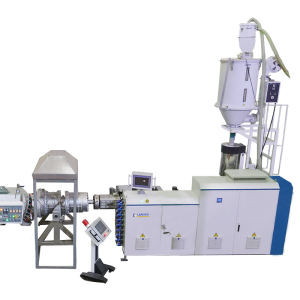

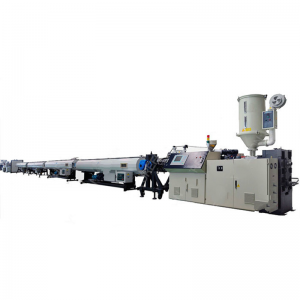

LB-MPP Pipe Extrusion Line

Raw Material—feeder—single screw extruder—mould and calibrator—vacuum forming machine— spraying cooling machine—haul-off machine—cutting unit— stacker.

| Model | Pipe range | Screw Model | Motor power | Total length | Max output |

| LB-63 | 16-63mm | SJ65 | 37KW | 22m | 80-120kg |

| LB-110 | 20-110mm | SJ75 | 55KW | 30m | 100-160kg |

| LB-160 | 50-160mm | SJ75 | 90KW | 35m | 120-250kg |

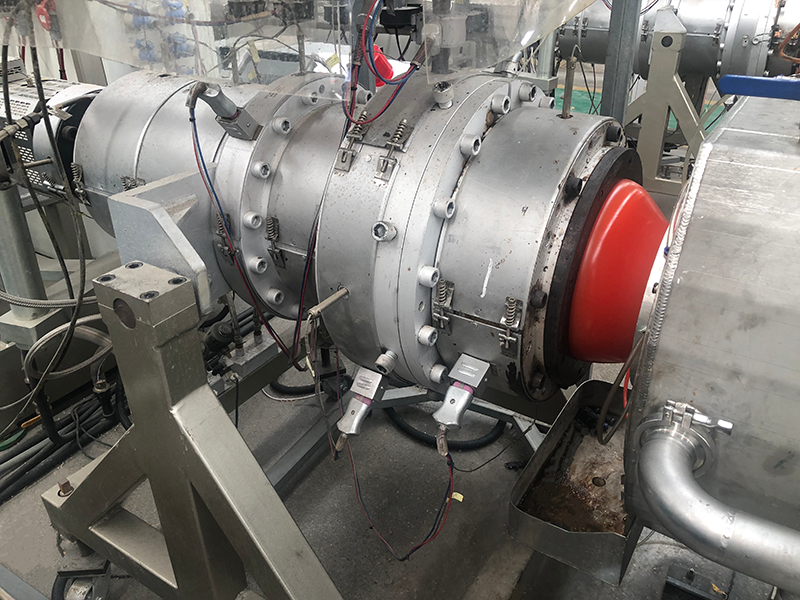

Single Screw Extruder & mould

The novel designed screw and barrel has better plasticizing effect. The clever matching between motor and screw based on production condition provide good performance and high output. We offer Siemens Motor and ABB Frequency inverter for worldwide after-sales service and easy maintainable. The PLC control system realized controlling the whole line in one site. Unique designed of flow channel for superb pipe shaping and reasonable melt pressure. The large spiral distributor ensures the excellent plasticizing effect and stable output of the plastic flowing.

Vacuum Calibration & Cooling tank

The vacuum and cooling unit equip frequency conversion control system for high energy conservation and high space saving. Adequate length of the vacuum and cooling calibration ensure the shaping and cooling of the MPP pipes.

Watering Tank

This line allocates high energy efficiency pump and large water tank for sufficient cooling time.

The whole body is 304 steel with sturdy structure design ensuring long lifetime.

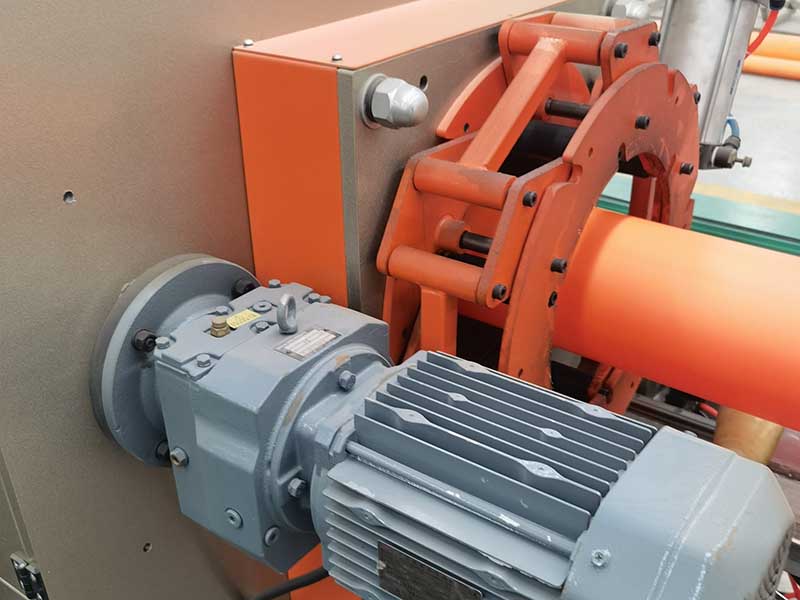

Haul-off Unit

The three caterpillar on the haul-off machine ensures produced pipe running stably and steady. We utilize a unique mechanism to prevent pipe ovality while our unique belt design assures proper pulling without slippage. Our pipe haul-off machine are servo motor driven to increase precision and production speed.

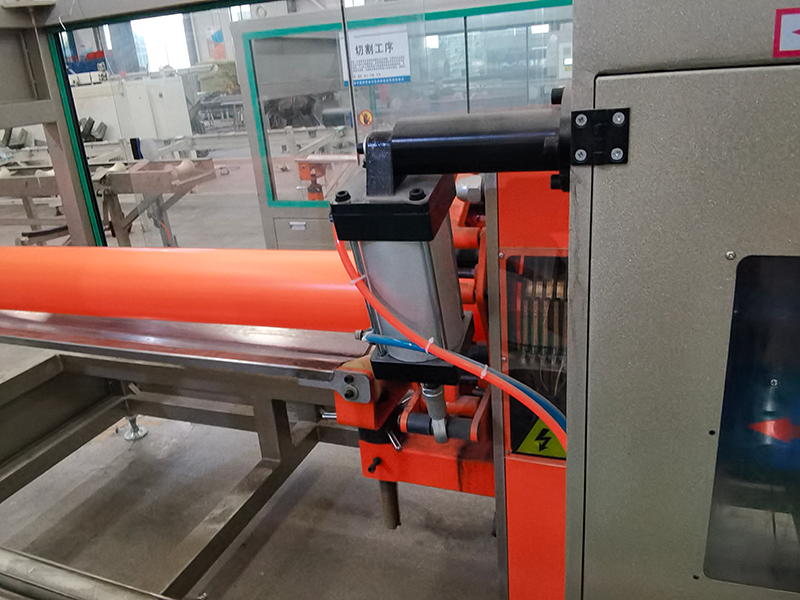

Rapid cutter

We provide rapid cutter for the MPP pipe production line as the extrusion speed on pipe is fast. The MPP production line has intelligent PLC control system. It can cut at the exact length getting fixed dimension products.