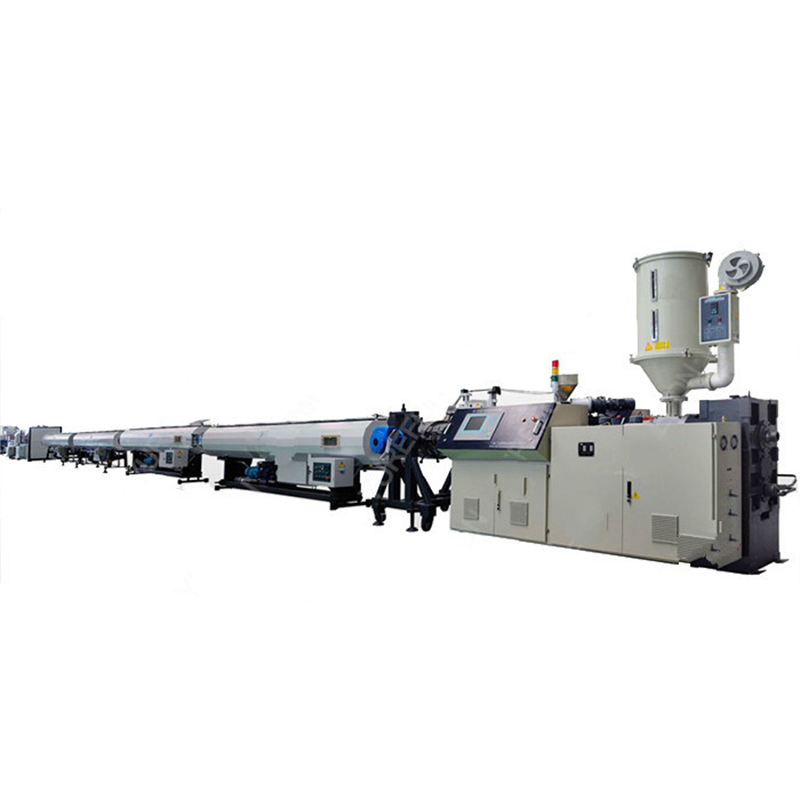

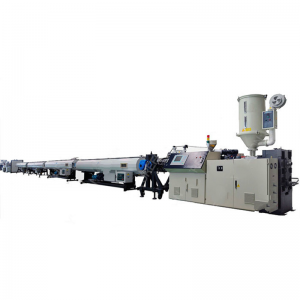

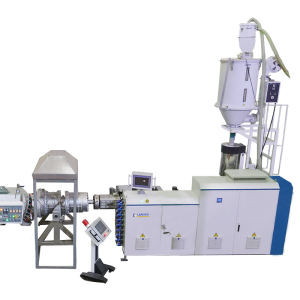

LB-PP-R/PE-RT Pipe Production Line

Material feeder—single screw extruder—mould and calibrator—vacuum forming machine— spraying cooling machine—haul-off machine—swarfless cutting unit—stacker.

The max production speed could be 35m/min (base on 20mm pipes).

For different requirements, the production line could also be used for making pipes with different diameters and wall thickness.

Double or four strand extrusion will improve the output capacity of the PP-R Production line.

The production of PE-RT or PP-R pipes can be realized by the appropriate transformation of the machine.

| Model | Pipe range | Screw Model | Motor power | Total length | Max output |

| LB-63 | 16-63mm | SJ65 | 37KW | 22m | 80-120kg |

| LB-110 | 20-110mm | SJ75 | 55KW | 30m | 100-160kg |

| LB-160 | 50-160mm | SJ75 | 90KW | 35m | 120-250kg |

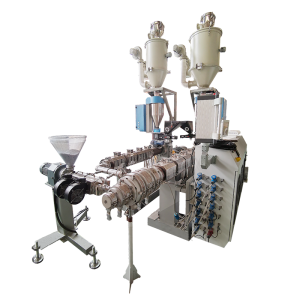

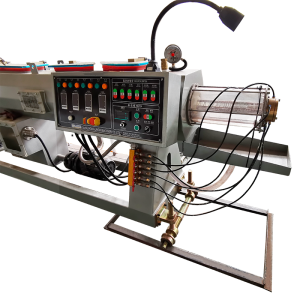

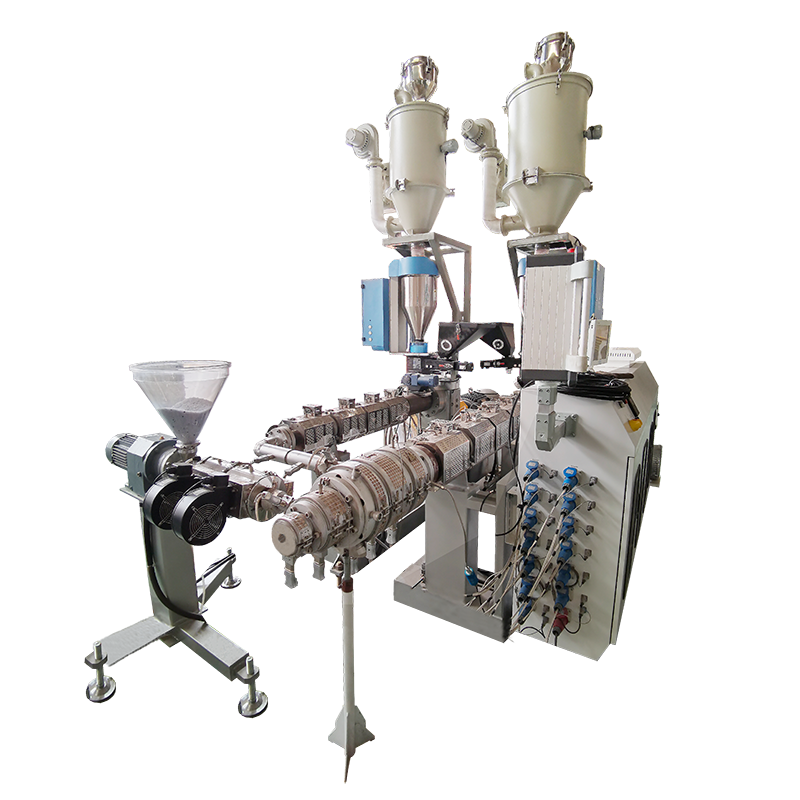

Single screw extruder machine

The extruder are crafted with top brand components to ensure production stability, efficiency and machine durability. Our extruder allocates international standard single screw and barrel. The screw has strong rigidity ensuring long service life and distinguished plasticizing effect. This pipe extrusion line adopt energy efficient single screw extruder with special mould, production efficiency increased by 30%, energy consumption lower than 20%.

Mould

The mould has spacious flow channel design to guarantee high extrusion capacity and good melting effect. It is made and inspected by the experienced manufacturer. The optimized temperature control and flow channel design ensures precise melt temperature control.

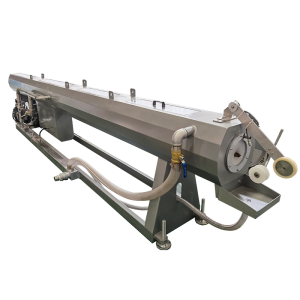

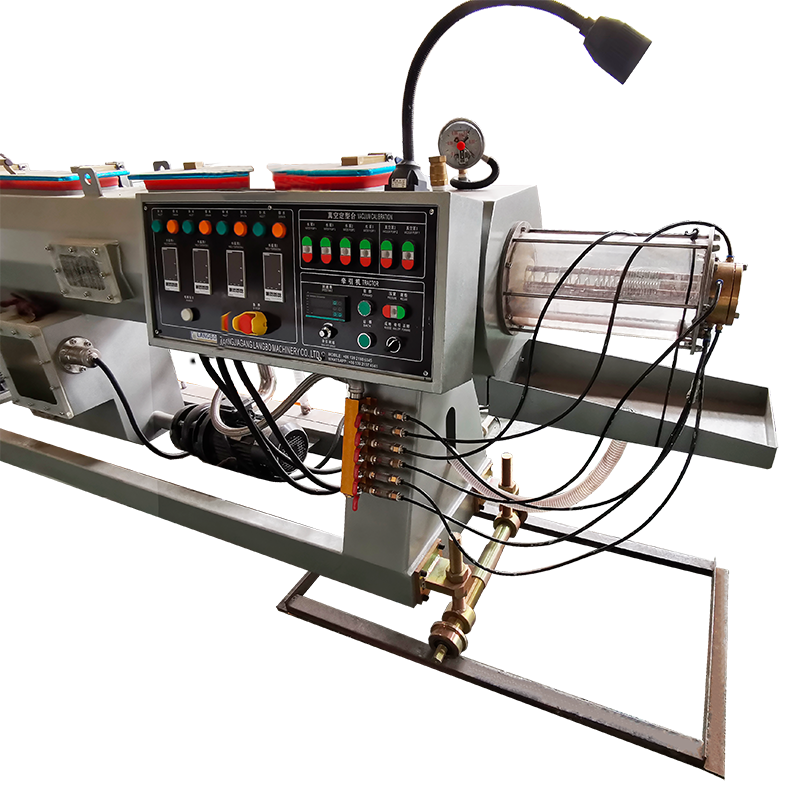

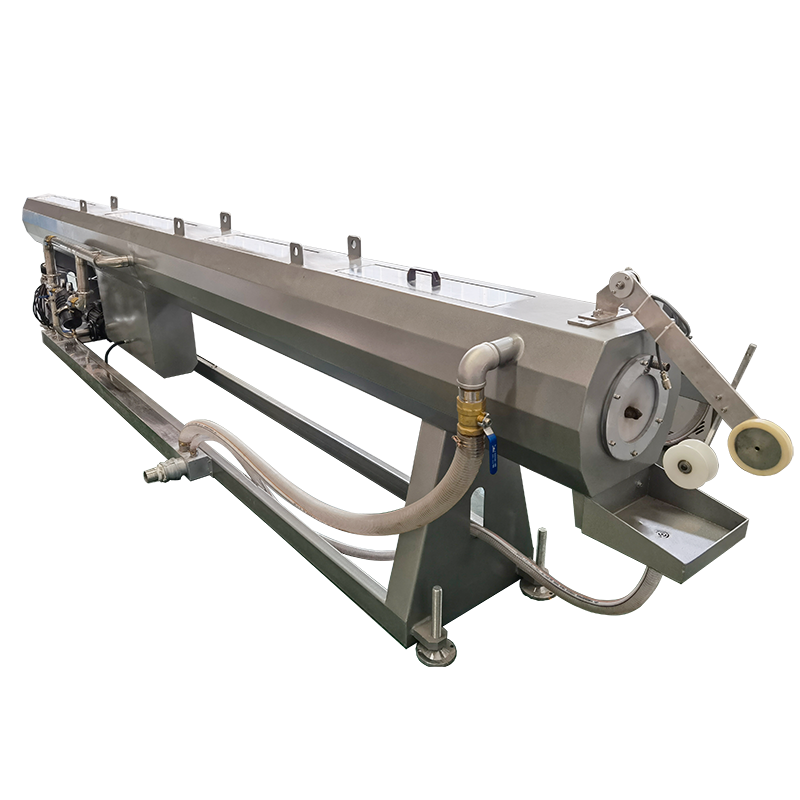

Vacuum Tank

All of our vacuum and cooling tanks are manufactured from 304 quality stainless material to prevent rusting. Our vacuum tanks are digitally controlled allowing for a completely automated process. The holder in first step of the vacuum calibration tank guarantees the pipe shaped and provides extra power for the pipes moving on.

Cooling tank

Adequate length of spraying and cooling will improve the cooling efficiency. Auto water temperature control system is adjusted according to the temperature sensing.

Haul-off Unit

The three caterpillar on the haul-off machine ensures produced pipe running stably and steady. We utilize a unique mechanism to prevent pipe ovality while our unique belt design assures proper pulling without slippage. Our pipe haul-off machine are servo motor driven to increase

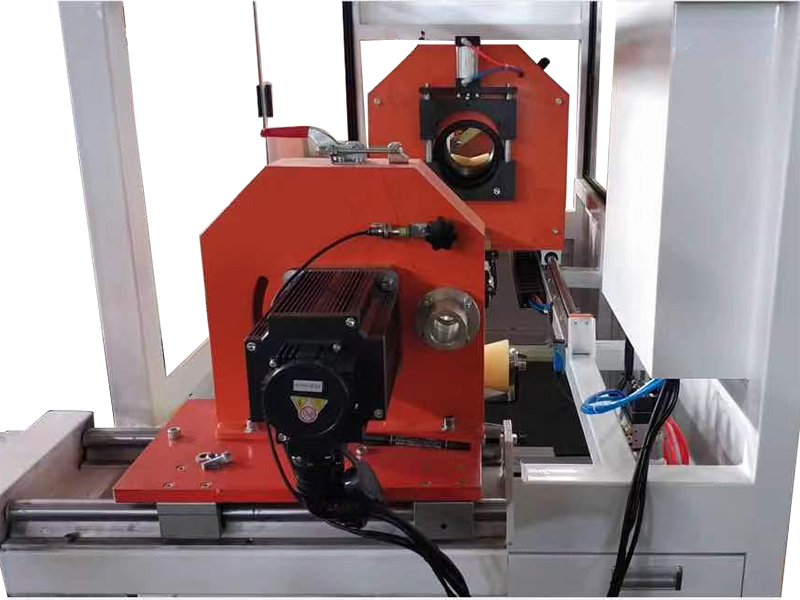

Rapid cutter

We provide rapid cutter for the PP-R production line as the extrusion speed on pipe is fast. The PP-R production line has intelligent PLC control system. It can cut at the exact length getting fixed dimension products.