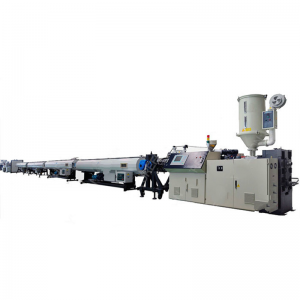

LB-PVC Pipe Production Line

PVC powder + additive — mixing—material feeder—twin screw extruder—mould and calibrator—vacuum forming machine—spraying cooling machine—haul-off machine—cutting machine—discharge rack or pipe belling machine.

| Model | LB160 | LB250 | LB315 | LB630 | LB800 |

| Pipe Range (mm) | 50-160mm | 75-250mm | 110-315mm | 315-630mm | 500-800mm |

| Screw Model | SJ65/132 | SJ80/156 | SJ92/188 | SJ92/188 | SJ92/188 |

| Motor power | 37KW | 55KW | 90KW | 110KW | 132KW |

| Output | 250kg | 350kg | 550kg | 600kg | 700kg |

Mixer

With specific design of mixer, the self-friction of raw materials is reduced. It is conducive to the efficiency of energy utilization. The Vacuum suction load with low noise and no-dust working situation.

Twin screw extruder machine

The extruder are crafted with top brand components to ensure production stability, efficiency and machine durability. Our conical twin screw extruder design cater to the raw materials feature ensuring homogeneous mixture, better plastification and conveying efficiency.

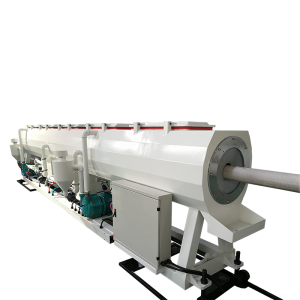

Vacuum Calibration & Cooling

The vacuum calibration tank adopt two chamber structure: the vacuum calibration and cooling parts. Both of vacuum tank and spraying cooling tank adopt stainless 304 steel. The excellent vacuum system ensures precise sizing for pipes.

Haul-off Unit

The three caterpillar on the haul-off machine ensures produced pipe running stably and steady. The haul-off units can make tailored hauling model based on certain production requirement by adjusting the general control.

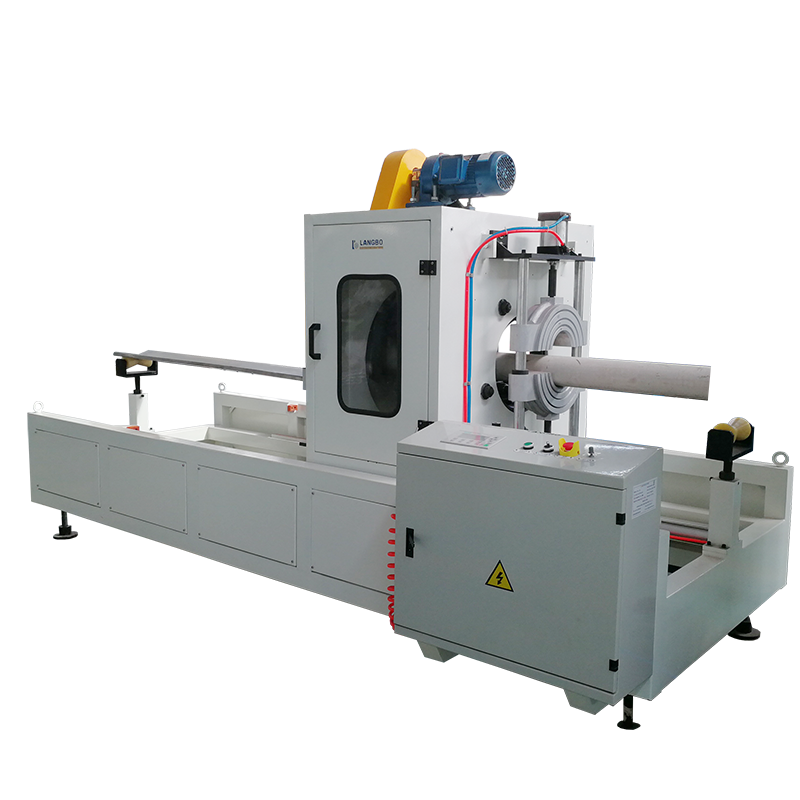

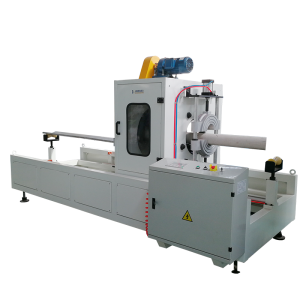

Cutting Unit

The high accuracy encoder ensures a precise and stable cutting length. With PLC control system, it can be cut by manual operation according to the specific application.