LB-Strand Cutting Granulating Line

| Model | Diameter(mm) | L/D | Speed(rpm) | Power(kw) | Output(kg/h) |

| LB40-B | 41 | 24-80 | ~600 | 30~37 | 100~130 |

| LB52-B | 51.4 | 24-80 | ~600 | 55~75 | 150~250 |

| LB65-B | 62.4 | 24-80 | ~600 | 90~110 | 300~400 |

| LB75-B | 71 | 24-80 | ~600 | 132~160 | 400~500 |

| LB85-B | 81 | 24-80 | ~600 | 220~250 | 700~800 |

| LB95-B | 93 | 24-80 | ~600 | 280~315 | 900~1000 |

| LB110-B | 110 | 24-80 | ~600 | 400~450 | 1000~1500 |

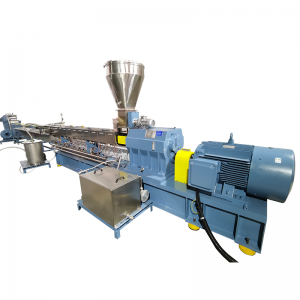

Parallel Twin Screw Extruder

Parallel Twin Screw Extruder

Heavy Load Gearbox for reliable running

High precise screw part for excellent screw building

High quality electrical parts and worldwide famous brand for drive unit

Easy Temperature setting and indication

Degassing section for tailored processing demand

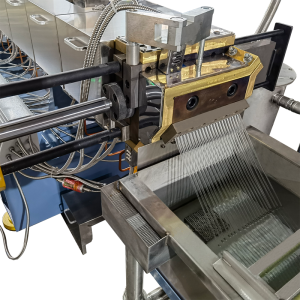

Hydraulic Melt filter Mould

304 Steel screens with tailored mesh size

Hydraulic plate or cylinder filter body available

Bronze heater for high heating efficiency

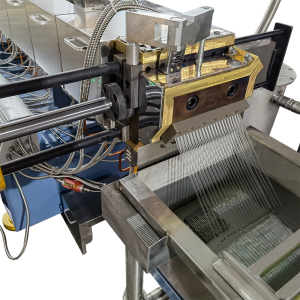

Water Tank Tempering

Water cycle for evenly temperature distribution and well cooling effect

Strand Holders adjust strand in the water for cooling and out of the water for drying

Advanced manufacture technology for robust structure and precise adjustment

Air Knife

High speed knife for strand dewatering

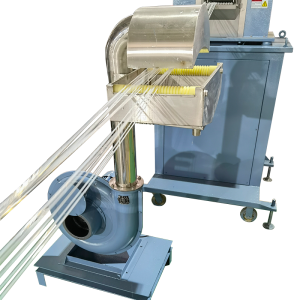

Pelletizer

Pelletizers are completely made of AISI 304 stainless steel. Pelletizing blades and die are made of special alloy steels and coatings according to the type of plastic. By mobile parts, maintenance period is minimized. Speed control for pelletizing blades enables changing granule size during operation.

Vibration Sieve

Granules’ size controlled by vibration sieve too small or too big granules will be flited out. The only granules, which fit the size requirement will be transported into storage silo by air.