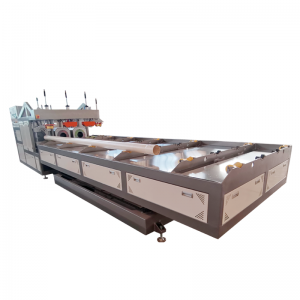

LB-U and R type PVC pipe belling machine

Caterpillar moving part:

Our belling machine has caterpillar transportation part to make the pipe moving forward. The belling machine is following the cutting part or used separately. When the pipe is put on the table of the belling machine, the caterpillar will transport the pipe to the heating oven.

Two heating ovens:

Ahead and below of the heating oven, it all has the caterpillar transporting device. It makes the pipe turning when the top of pipe is in the heating oven. By the turning action, the pipe surface is well heating evenly.

Belling oven:

After twice heating in the heating oven, the pipe edge is soft and easy shaped. In the belling oven, it is totally vacuum with water spraying in order to make the belled pipe keeping the U or R shape. After the belling, we have push out device. Pushing the finished pipe outside the oven and work continuously.

Heating System is adopted with the Infrared heaters, which has high efficiency in heating pipe extremely for mid or high wall-thickness. It can provide a homogenous heating for the pipe.

The pipe temperature is directly monitored and regulated.

With the optimized programmed control system the heating time and step of the transportation can achieve a high performance and energy saving result.

Moreover, Inferred heaters provides homogenous heat inside the pipe. The pipe surface temperature will be constantly measured, and the temperature controls the emission of the heating power directly.

High precise socket shaping component and high quality electrical component ensures a long service time and reliable production.

The technical configuration of the pipe belling machine should fit the production conditions. If you are interested in the belling machine, please contact us for more detailed information. We are looking forward to providing you our professional suggestions about the customized cutter unit solution and the whole production line.