LB-Water slide String granulating line – Langbo

LB-Water slide String granulating line – Langbo Detail:

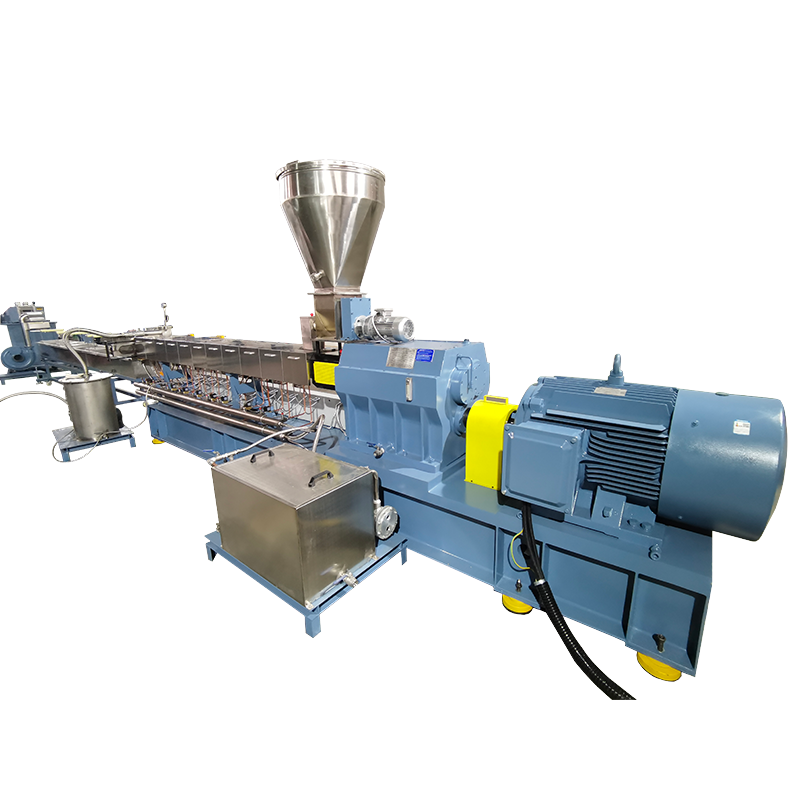

LB Machinery offers high efficiency strand cutting granulating line. A perfect combination provides a high efficiency running between extruder and downstream equipment. Our strand cutting granulating line ensures high product specification and high production yields.

Extruder:→Water Bath Cooling:→Air Knief Drying:→Rotor of Pelletizer:→Vibrating Sieve→Collection Bag

Extruder:

LB Machinery offers single screw extruder for the PE or PPR strand cutting pelltizing as well as twin screw extruder for PVC strand pelletizing line. We pull off the raw material into the feeder and extrude plasticizing stand.

Water Bath Cooling:

In the water bath, the raw material strand was cooled and moving forward together with the flowing water. During the forward movement, the plasticizing strand harden and cooling.

Air Knief Drying:

Getting through the water bath cooling, the plasticizing strand are dried by the air knief. The blowing wind takes away the excess moisture that is the preparation for the pelletizing.

Rotor of Pelletizer:

Our pelletizer utilize the helical blades of bolt-on blades. The blade runs at a high speed continuously to cut out the uniform-sized granules.

Vibrating Sieve

The granules out the pelletizer go through the vibrating sieve. Under the high frequency vibrating, the granules can be figure out into big, medium and small. Through processing, we can get particles of uniform size.

Screen Changer:

It is optional. The screen changer is used to filter the impurities. If the granulated material is purity, the screen changer is unnecessary.

Equipment Color:

We offer customized equipment color. Plenty of machine color is available.

Product detail pictures:

Related Product Guide:

Adhering for the theory of quality, services, performance and growth, we have received trusts and praises from domestic and worldwide shopper for LB-Water slide String granulating line – Langbo, The product will supply to all over the world, such as: Gabon, Toronto, Chile, All of our products comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients in the near future.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.