LB_32-63mm PVC Pipe Extrusion Machine

| MODEL | PIPE DIAMETER (MM) | EXTRUDER MODEL | MOTOR POWER |

| LB-63A | 16-63 | SJSZ51/105 | 22 AC |

| LB-63B | 16-63(DOUBLE PIPE) | SJSZ65/132 | 37 AC |

| LB-160 | 50-160 | SJSZ65/132 | 37 AC |

| LB-250A | 63-250 | SJSZ65/132 | 37 AC |

| LB-250B | 63-250 | SJSZ80/156 | 55 AC |

Place of Origin:Jiangsu, China (Mainland)

Plastic Type: PVC

Making pipe diameter: 20-63mm

Machine Type: PVC Double Strand Extrusion Line

Voltage: 380V,3Phase,50HZ(customerized)

Warranty:1 years

Brand Name: Langbo

Production Capacity (kg/h): 400

Haul off type: Belt haul off

Max.Production Capacity (kg/h): 600-800

Power (kW):55kw

Key Selling Points:High quality

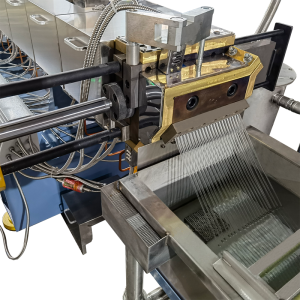

Twin screw extruder machine

The extruder are crafted with top brand components to ensure production stability, efficiency and machine durability. Our conical twin screw extruder design cater to the raw materials feature ensuring homogeneous mixture, better plastification and conveying efficiency.

Vacuum Calibration & Cooling

It has 6 meter long with several water nozzle for cooling. Our worker installed and adjusted the position carefully in order to make good utilization. It is full of water nozzle. And the double strand pvc pipe will be gone through the water. This way is useful for the cooling and makes pipe harder.

Haul-off and cutter combination

We adopt two belt haul-off machine. It can haul off two pvc pipe at the same time. On its behind is the cutter. It has coder. It counts the length of the pipe and cut at the exact point. And finally all the pvc pipe will be same length and easy for transporting and packing.

Stacker

It is the holder for the pvc pipe. The pipe will be lying on there. And workers can pack them one by one.