LB_75-315mm PVC Pipe Extrusion Line

| MODEL | PIPE DIAMETER (MM) | EXTRUDER MODEL | MOTOR POWER | CAPACITY(KG/H) |

| LB-250 | 63-250 | SJSZ65/132 | 37 AC | 250 |

| LB-315 | 75-315 | SJSZ80/156 | 55 AC | 350 |

| LB-630 | 315-600 | SJSZ92/188 | 110 AC | 800 |

| LB-800 | 560-800 | SJSZ105/216 | 160 AC | 1100 |

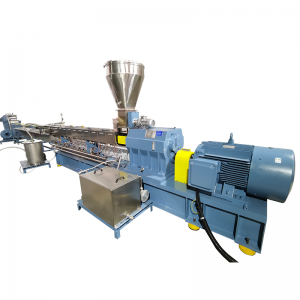

Twin screw extruder machine

The extruder are crafted with top brand components to ensure production stability, efficiency and machine durability. Our conical twin screw extruder design cater to the raw materials feature ensuring homogeneous mixture, better plastification and conveying efficiency.

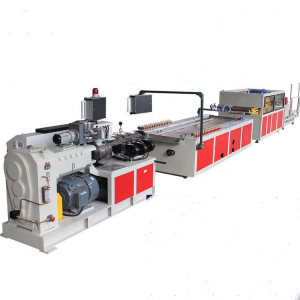

Vacuum Calibration & Cooling

It has 6 meter long with several water nozzle for cooling. Our worker installed and adjusted the position carefully in order to make good utilization. It is full of water nozzle. And the double strand pvc pipe will be gone through the water. This way is useful for the cooling and makes pipe harder.

Haul-off Machine

We adopt three caterpillar haul-off machine. It can haul off the 75-315mm pvc pipe running stably. We adopt good quality rubber and chain. It equipped with three sets motor and gearbox to control each of three. Meanwhile it has cylinder to adjust the haul-off up and down.

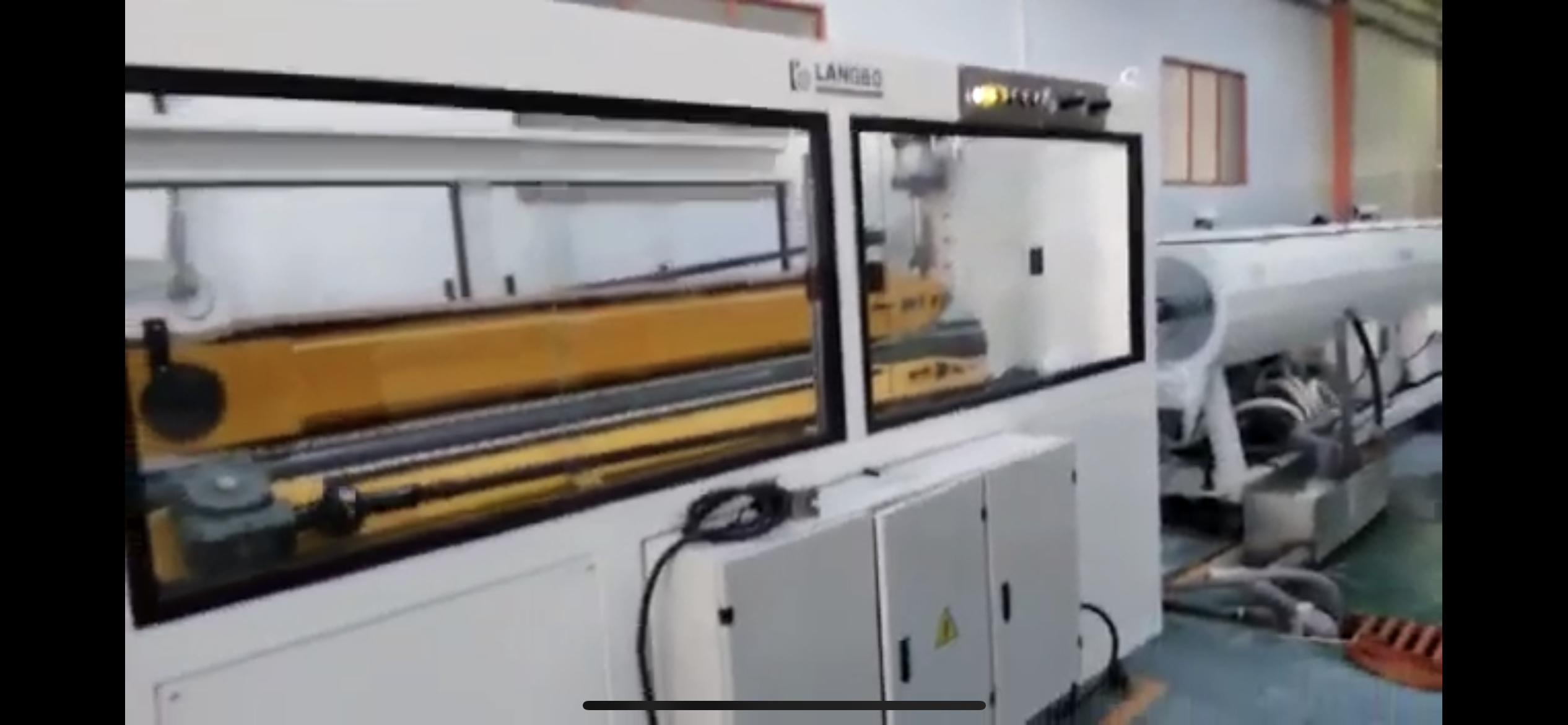

Cutter Unit

Our cutter unit has PLC control system. It has encoder to encode the length and cut at exact point. The whole process is full automatically.Before sending to customers’ site, we will program and adjust it. It adopts planetary cutting method. At present, we also have lights in the observation window.

Belling Machine

Our belling machine adopts most advanced technology as Turkish belling machine. It has two heating oven. After heating from one oven to another, the pvc pipe will be sent to be belled. In the belled chamber, the belled pipe will be spraying water to cooling. And we adopt push power to separate the belled pipe and the equipment. It has very excellent effects.