-

Common Causes of Defective Finished Products and Solutions About Plastic Extrusion Line

Defective finished products can be a real headache for manufacturers, impacting everything from customer satisfaction to the bottom line. Whether it’s a scratch on the surface, an off-spec measurement, or a product that just doesn’t work as it should, understanding why these defects h...Read more -

How to produce the cpvc pipe successfully

Due to the characteristics of cpvc raw material, the screw, barrel, die mould, haul-off and cutter design differs from the upvc pipe extrusion line. Today let’s focus on the screw and die mould design. How to modify the screw design for cpvc pipe extrusion Modifying the screw design for CPVC p...Read more -

Features and Applications of C-PVC pipe

What is C-PVC CPVC stands for Chlorinated Polyvinyl Chloride. It is a type of thermoplastic produced by chlorinating PVC resin. The chlorination process improves the portion Chlorine from 58% to 73%. The high chlorine portion makes the features of C-PVC pipe and production processing significant ...Read more -

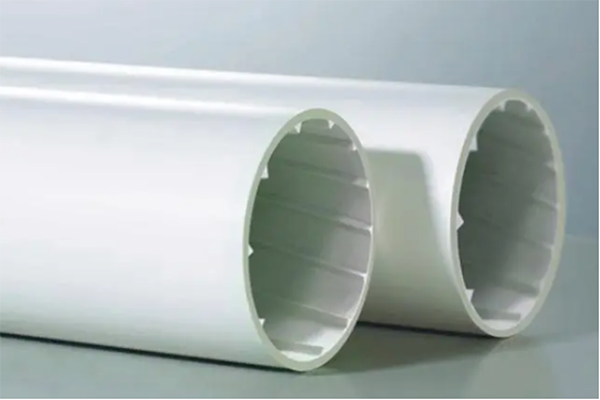

Features of PVC silencing pipes

First, the source purpose of the PVC silencing pipes In modern cities, people gather in buildings because the drains in the kitchen and bathroom are the source of noise in the home. In particular, thick pipes can make a lot of noise when used by others in the middle of the night. Many people who ...Read more -

The revolutionary impact of plastic extrusion technology on sustainable manufacturing

In today’s industrial landscape, sustainability has become a top concern for manufacturers around the world. As industries strive to reduce their environmental footprint, plastic extrusion technology is a key player in promoting environmentally friendly production practices. Langbo Machiner...Read more -

Components of a PE Pipe Extrusion Line

As a leading manufacturer and supplier in the plastic processing industry, Lambert Machinery provides high-quality PE pipe extrusion lines designed to meet the diverse needs of customers. In this comprehensive guide, we’ll explore what a PE pipe extrusion line is, its components, the production p...Read more -

How to choose the right plastic granulator

As the demand for plastic pellets continues to grow across industries, choosing the right plastic pelletizer is crucial to ensuring high-quality output and efficient production. There are a variety of granulators on the market, and several key factors must be considered to make an informed decisi...Read more -

Unleashing the Power of Shredding:

Double Shaft and Single Shaft Shredders The world of document and material shredding has witnessed remarkable advancements in technology,presenting users with a wide range of options to choose from.Two popular choices are the double shaft shredder and the single shaft shredder.Both types of shred...Read more -

Define the suitable pipe extrusion line for your factory –size range of pipe production

A big size range is not always the best choices. A pipe extrusion line can produce several kinds of pipe size. The selection range of pipe size is usually the first step in the configuration of the pipe extrusion line. The selection the size range should base on the following factors: Sales m...Read more -

Comparison of single-screw and twin-screw extruders

(1) Introduction of single screw extruder Single-screw extruders, as the name suggests, have a single screw inside the extruder barrel. Generally, the effective length is divided into three sections, and the effective length of the three sections is determined according to the screw diameter, pit...Read more -

Cleaning methods of plastic extruder

First, choose the correct heating device Removing the plastic fixed on the screw by fire or roasting is the most common and effective method for plastic processing units, but acetylene flame should never be used to clean the screw. Correct and effective method: use a blowtorch immediately after t...Read more -

Principles of extruder

01 Mechanical principles The basic mechanism of extrusion is simple–a screw turns in the cylinder and pushes the plastic forward. The screw is actually a bevel or ramp that is wound around the central layer. The aim is to increase the pressure in order to overcome greater resistance. In the case ...Read more