OEM Customized Profile Sheet Making Machine - LB-WPC Profile Extrusion Line – Langbo

OEM Customized Profile Sheet Making Machine - LB-WPC Profile Extrusion Line – Langbo Detail:

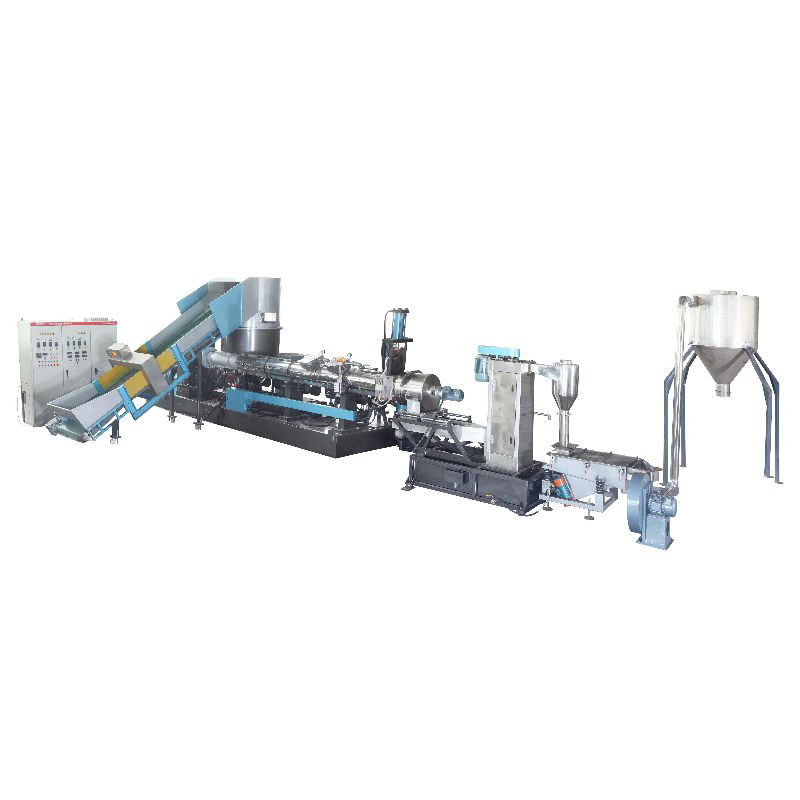

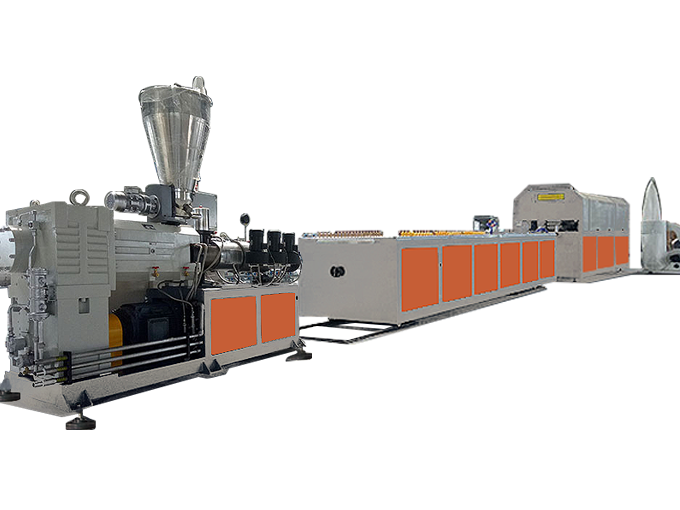

The process flow of this line is PP/PE/PVC + wood powder + additive— mixing—material feeder—twin screw extruder—mould —Calibration table—cutting unit—discharge rack.

This WPC profile extrusion line adopts conical twin screw extruder, which has degassing system to ensure the excellent material plasticization. The mold and calibrator adopt wearable material; the haul-off machine and cutter machine could be designed as complete unit or separate machine.

| Model | LB180 | LB240 | LB300 | LB600 |

| Max width of products(mm) | 180 | 240 | 300 | 600 |

| Screw Model | SJ55/110 | SJ65/132 | SJ65/132 | SJ80/156 |

| Motor power | 22KW | 37KW | 37KW | 55KW |

| Cooling Water(m3/h) | 5 | 7 | 7 | 10 |

| Compressor(m3/h) | 0.2 | 0.3 | 0.3 | 0.4 |

| Total length(m) | 18m | 22m | 22m | 25m |

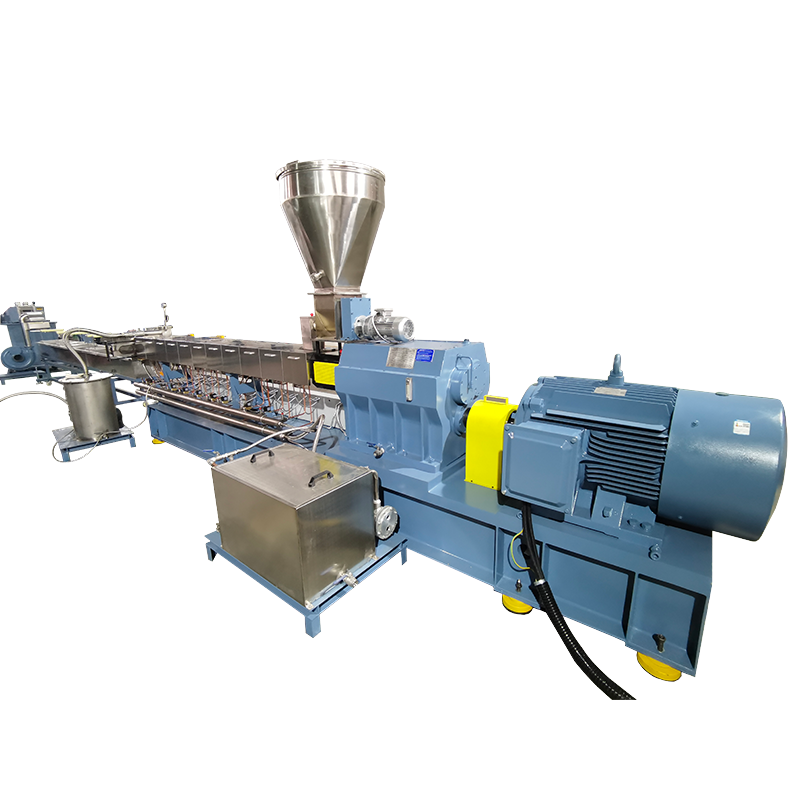

Conical Twin Screw Extruder

The screws are specifically designed and manufactured for the processing of WPC powder blend. The permanent magnet synchronous motor has high energy utilization. Equipped with PLC control system on the board, it realized controlling the whole production line in the one site.

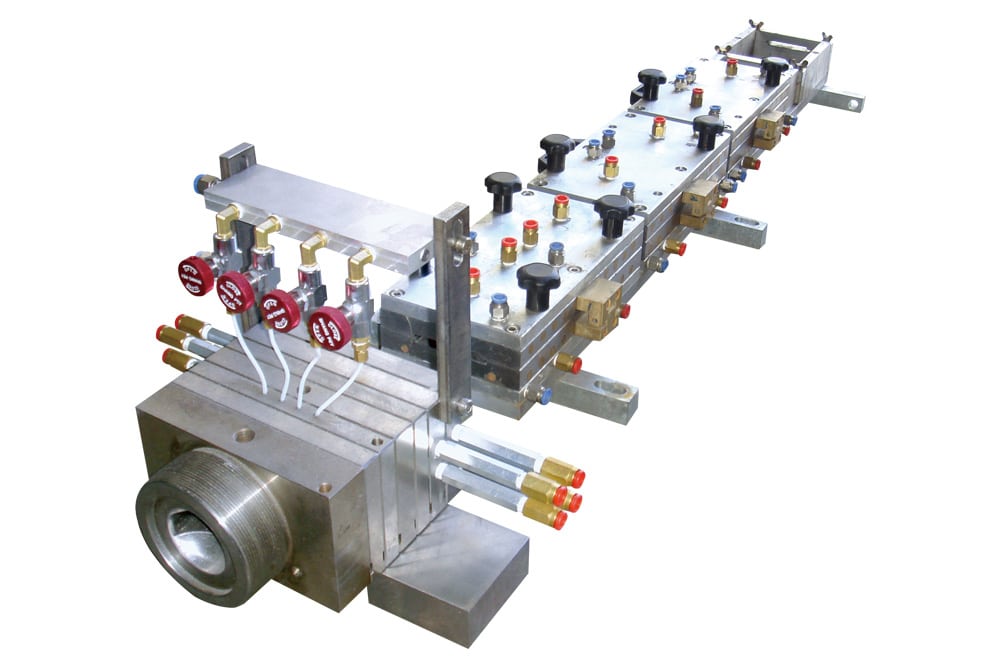

Plate Mould

We offer double Strand mould for the WPC profile extrusion line. By this way, the productivity will be highly improved. The optimized channel design ensures high flow performance. The advanced plate mould produced the profile with high precision.

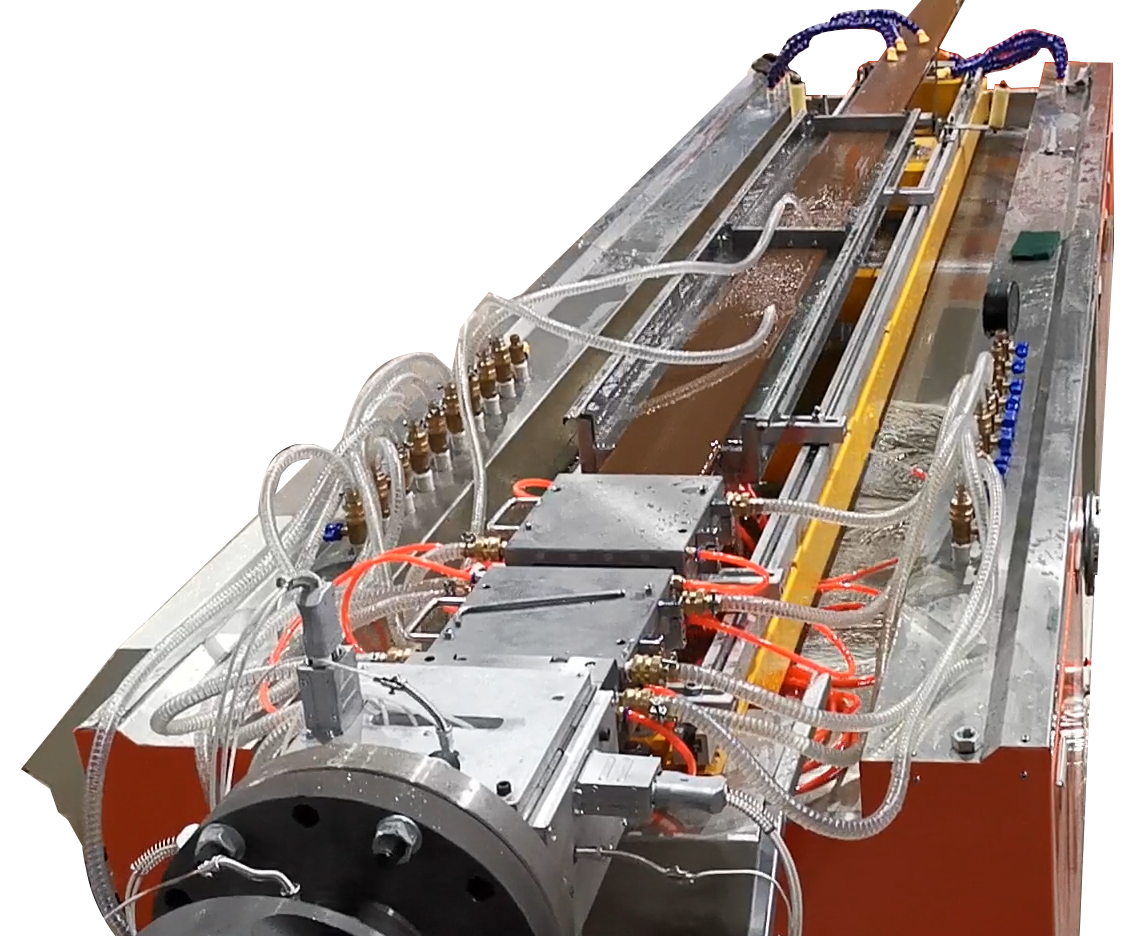

Calibration table

The calibration table has stable steel frame and the whole body material is SUS 304 stainless steel. We have multi-dimension position adjustment system. With precious layout of water pumps and vacuum calibrator, the WPC profile will be rapidly shaping and cooling. Enough length of the calibration table ensures the shaping of the WPC profile

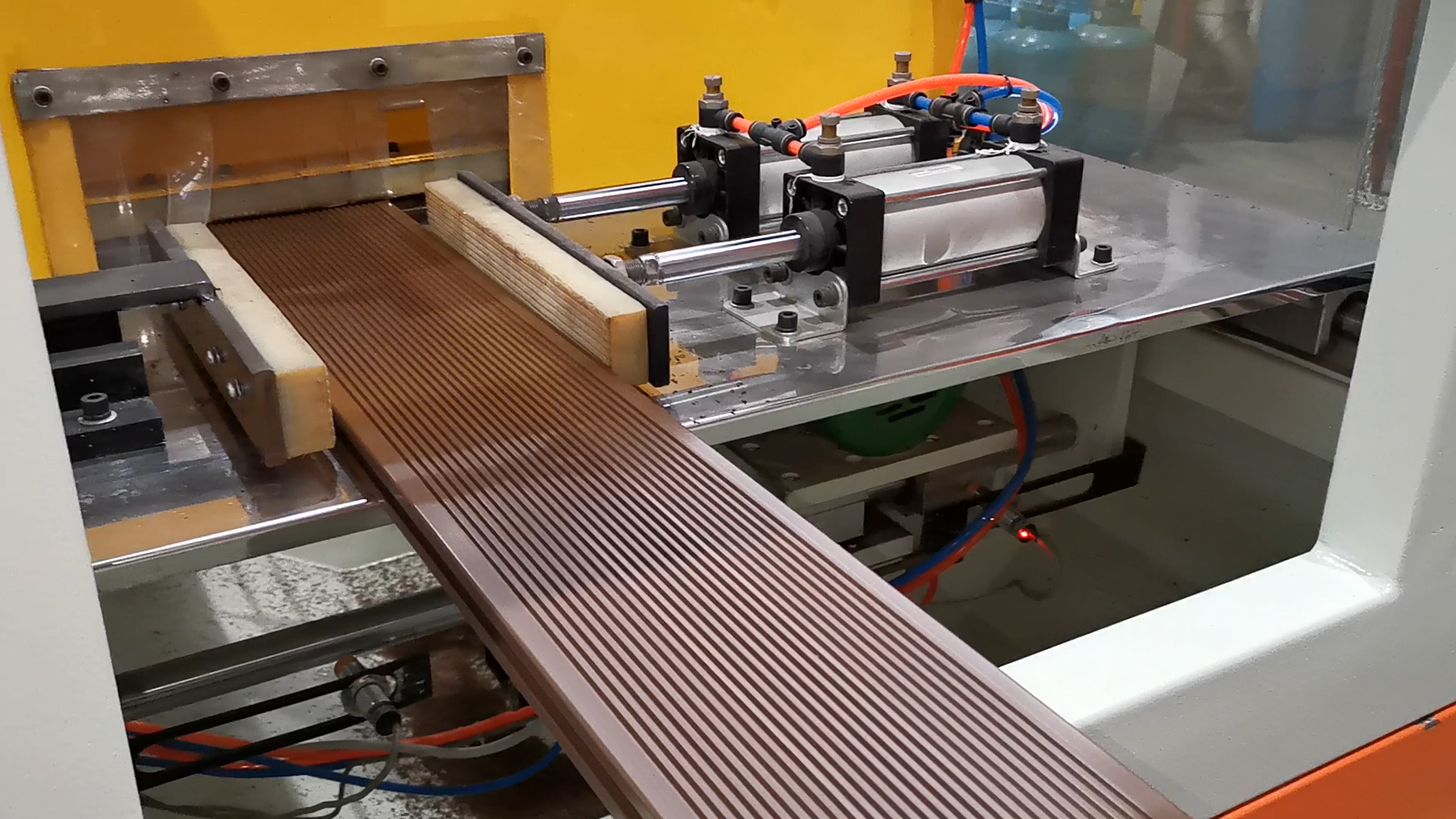

Cutter Unit

We provide saw cutter for the wpc profile production line. With the rotating of the saw, the wpc profile will be cut at the designated length. With the automatic control system on the unit, the whole process is intelligent and easy-operation.

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for OEM Customized Profile Sheet Making Machine - LB-WPC Profile Extrusion Line – Langbo, The product will supply to all over the world, such as: Italy, Madrid, Iceland, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our goods. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do for you personally always.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.