Original Factory Crusher And Shredder - LB- PP/PE Film/Bag/Rigid scraps Washing& Recycling Line – Langbo

Original Factory Crusher And Shredder - LB- PP/PE Film/Bag/Rigid scraps Washing& Recycling Line – Langbo Detail:

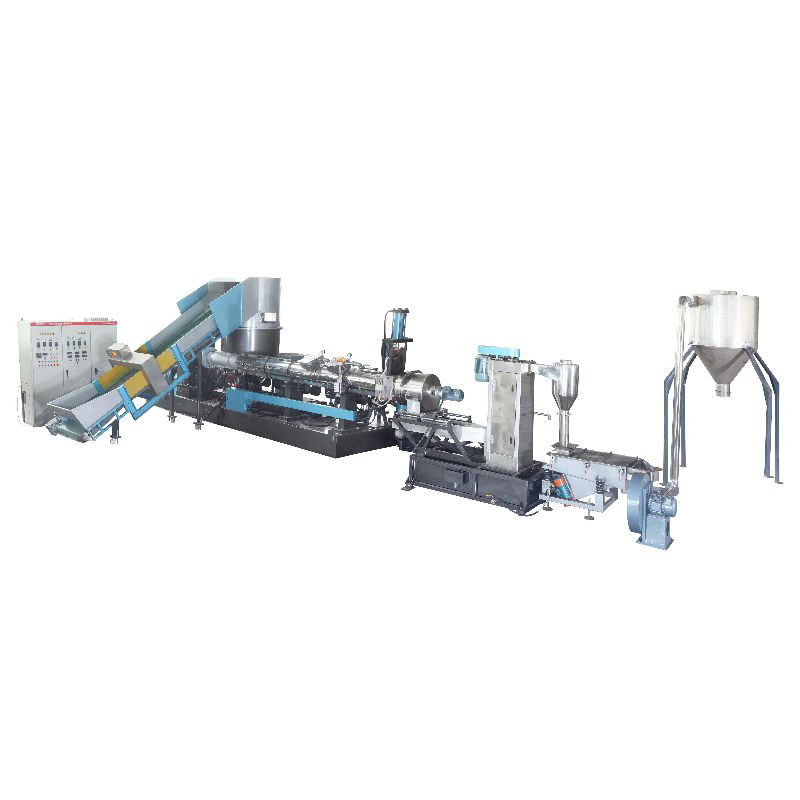

LB Machinery PP/PE Film/Bag/Rigid scraps Washing& Recycling Line

PP/PE Film and bag is pervasive in our life. Meanwhile, it is an important part in the plastic recycling and processing industry. Through crushing the wasted film/Bag, we obtain small particle scrapes. After cold and hot water washing, we acquire clean and soft flakes or rigid scraps. Those clean scrapes is used for the next application. The process and re-sale is economical and eco-friendly which is a promising business.

Langbo Machinery has over 12 years experience in the LB Machinery PP/PE Film/Bag/Rigid scraps Washing& Recycling Line. We offer the recycling line to industry worldwide, and our recycling program is designed to reduce operating costs and obtain quality PET flakes.

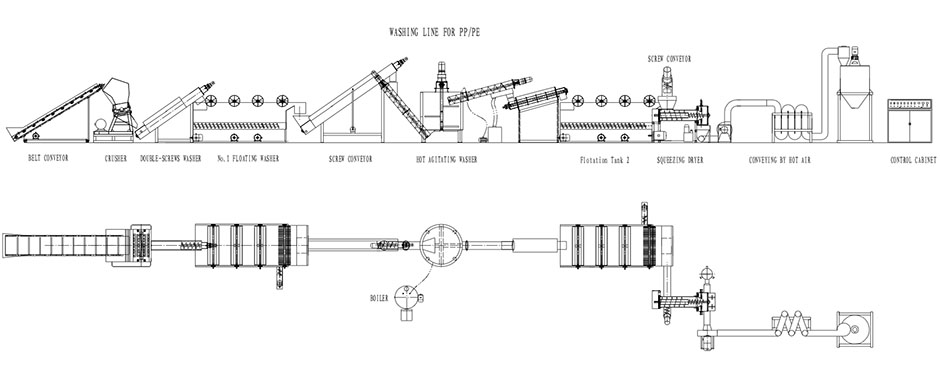

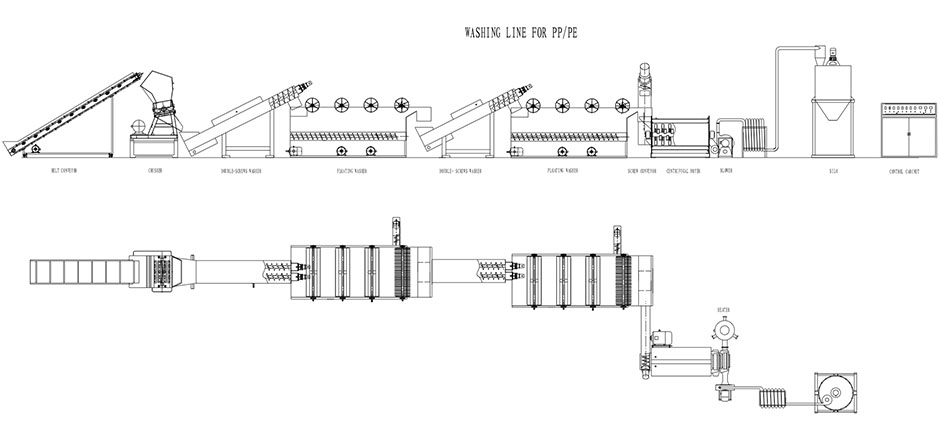

The processing procedure of the complete washing line consists of conveying – crushing – floating washer with cold water – agitating washer with hot water – floating washer with cold water – centrifugal drying/squeezing drying – collection.

➢ Belt conveyor

➢ Shredder&crusher

➢ Hot Washer

➢ Centrifugal Dryer

➢ Cold Washer

➢ Floating Washer

➢ Collection

➢ Applicable material: PP, HDPE, LDPE, LLDPE, etc..

➢ Materials shape: woven bag, printed films, agricultural film, raffia and rigid scraps.

The production capacity can be 300kg/hr, 500kg/hr, 1000kg/hr.

Note: Depending on material shape, some units involved in complete line will be changed and available.

Complete washing & recycling line

Crusher recycling

Double screw friction washer recycling

Floating cold washer recycling

Friction and hot washing

Product detail pictures:

Related Product Guide:

Our enterprise aims to operating faithfully, serving to all of our prospects , and working in new technology and new machine frequently for Original Factory Crusher And Shredder - LB- PP/PE Film/Bag/Rigid scraps Washing& Recycling Line – Langbo, The product will supply to all over the world, such as: Mexico, Burundi, Nepal, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a should for you personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We are confident that we'll have a vibrant prospect and to be distributed all over the world in the years to come.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!