Popular Design for Pvc Pipe Cutter - LB-Extruder – Langbo

Popular Design for Pvc Pipe Cutter - LB-Extruder – Langbo Detail:

Extruder is a the core of the whole production line. In the production process, the extruder plays the transporting and plasticizing function. Through feeder, the powder pulling into the screw and barrel part, it is heated, mixed and extruded into definite product. A good extrude will ensure the consistent production and saving more energy in the continuous extrusion.

Price factor: Single screw extruder is cheaper and simpler inner structure.

Plasticizing factor: The single screw extruder is more suitable for extrusion and processing of granular materials. It has little shear degradation of the polymer but long residence time of the material in the extruder.

Processing capacity and energy consumption: Single screw extruder has lower extruder output, extrusion speed, energy consumption and per unit of output.

Operability: Single screw extruder is easy manipulation and simple process control.

Common materials: PE PPR

Price factor: Twin screw extruder is more expensive and has complicated inner structure.

Plasticizing factor: The twin screw extruder has good mixing and plasticizing ability, short residence time of material in the extruder. It is more suitable for powder processing.

Processing capacity and energy consumption: Twin screw extruder has better extruder output, extrusion speed, energy consumption and per unit of output.

Operability: Twin screw extruder is difficult manipulation and complex process control.

Common materials: PVC

➢ Gearbox

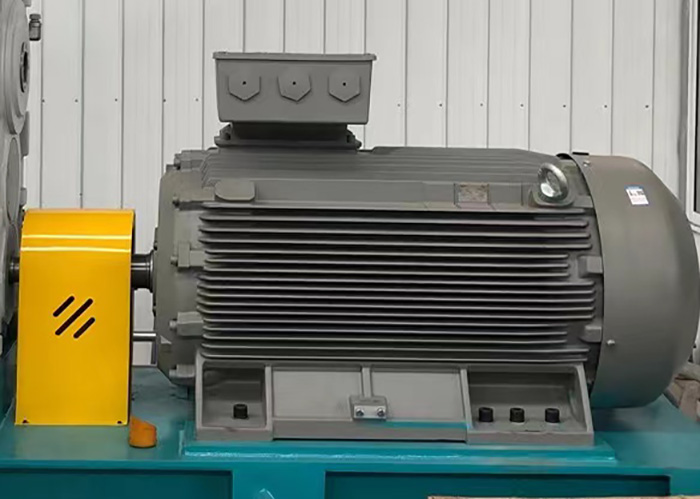

Extruder features ABB/Siemens motor&drive.

➢ Screw&barrel

Our extruder utilize the high quality screw& barrel.

➢ HMI/P: C

Our extruder has a 12 inch HMI comprised of components from Siemens/Omron.

➢ Electronics

Our Extruders offer Siemens/Schneider Electronics.

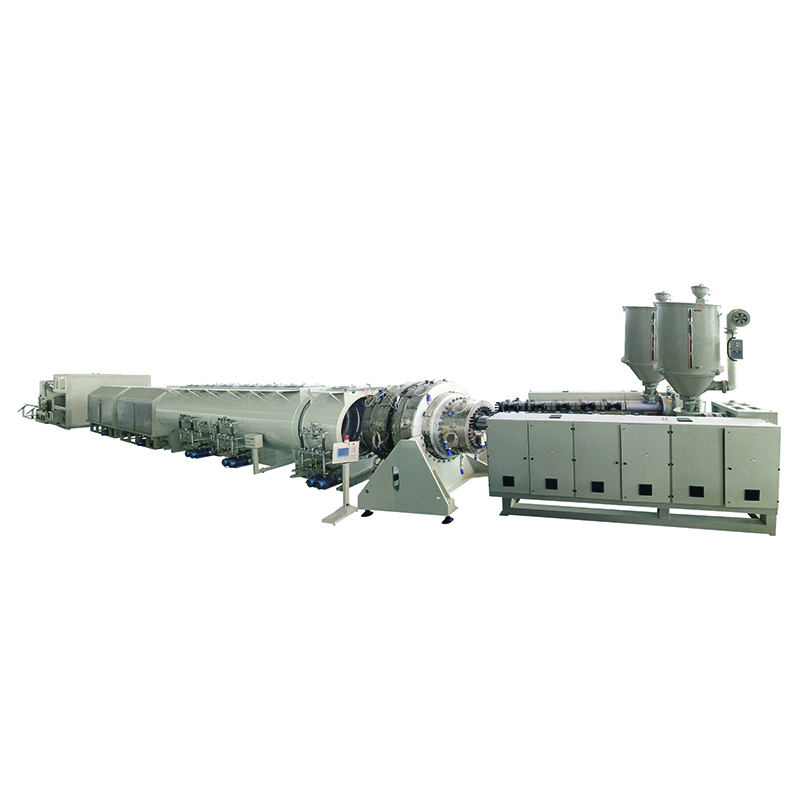

Conical twin screw extruder

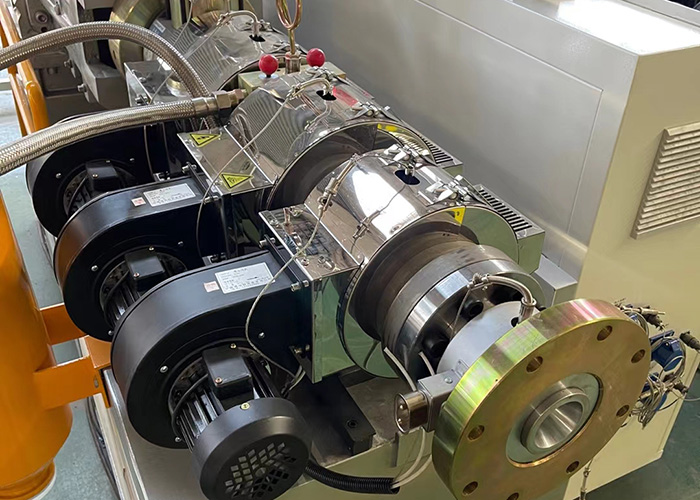

Details of the second stage extruder

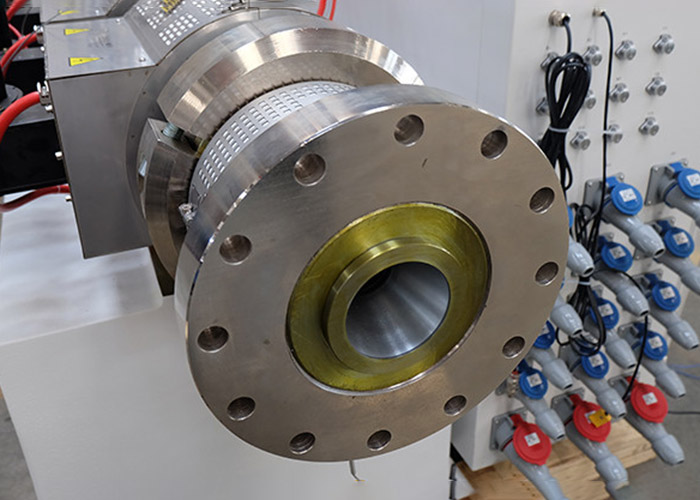

Flange surface by nickel-coating treatment

Integrated vertical type gearbox

Motor power

Overview Conical twin screw extruder

Product detail pictures:

Related Product Guide:

The business keeps to the operation concept scientific management, premium quality and efficiency primacy, customer supreme for Popular Design for Pvc Pipe Cutter - LB-Extruder – Langbo, The product will supply to all over the world, such as: Morocco, Tanzania, Argentina, Due to the stability of our products, timely supply and our sincere service, we are able to sell our products not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our to serve your company, and establish a successful and friendly cooperation with you.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!