-

400KG/H PVC Pelletizing Line/Machine/PVC Granulating Line

Langbo Machinery manufactures the specific water ring pelletizing line, which combines high efficiency running and stable productivity. Based on our mature technology and close contact with our customer we provide not only validated pelletizing equipment but also comprehensive solution.

-

PVC PP PE Plastic Powder Hot Cutting Pelleziting Granulating Granulator Machine/Pelletizer Line

Langbo Machinery manufactures the specific water ring pelletizing line, which combines high efficiency running and stable productivity. Based on our mature technology and close contact with our customer we provide not only validated pelletizing equipment but also comprehensive solution.

-

20mm-110mm Glassfiber PPR Pipe Making Machine/PPR Pipe Production Line/PPR Tube Machine

Multi-Layer pipes are produced by co-extrusion pipe line. The production line is a kind of special craft processes which can save the cost of raw material and make a series of pipes with functional features.

For Example, in order to save the cost of raw material, we can use the recycled material which is to be the middle layer to produce the PE thick wall pipes. For hot water supply pipes, the production line could not only have the PP-R Layer but also increase some other structure Layer including glass fiber, which attach the pipe to some excellent application features.

-

High Performance 16-63mm PPR Pipe Co-extrusion Machine Production Line

Multi-Layer pipes are produced by co-extrusion pipe line. The production line is a kind of special craft processes which can save the cost of raw material and make a series of pipes with functional features.

For Example, in order to save the cost of raw material, we can use the recycled material which is to be the middle layer to produce the PE thick wall pipes. For hot water supply pipes, the production line could not only have the PP-R Layer but also increase some other structure Layer including glass fiber, which attach the pipe to some excellent application features.

-

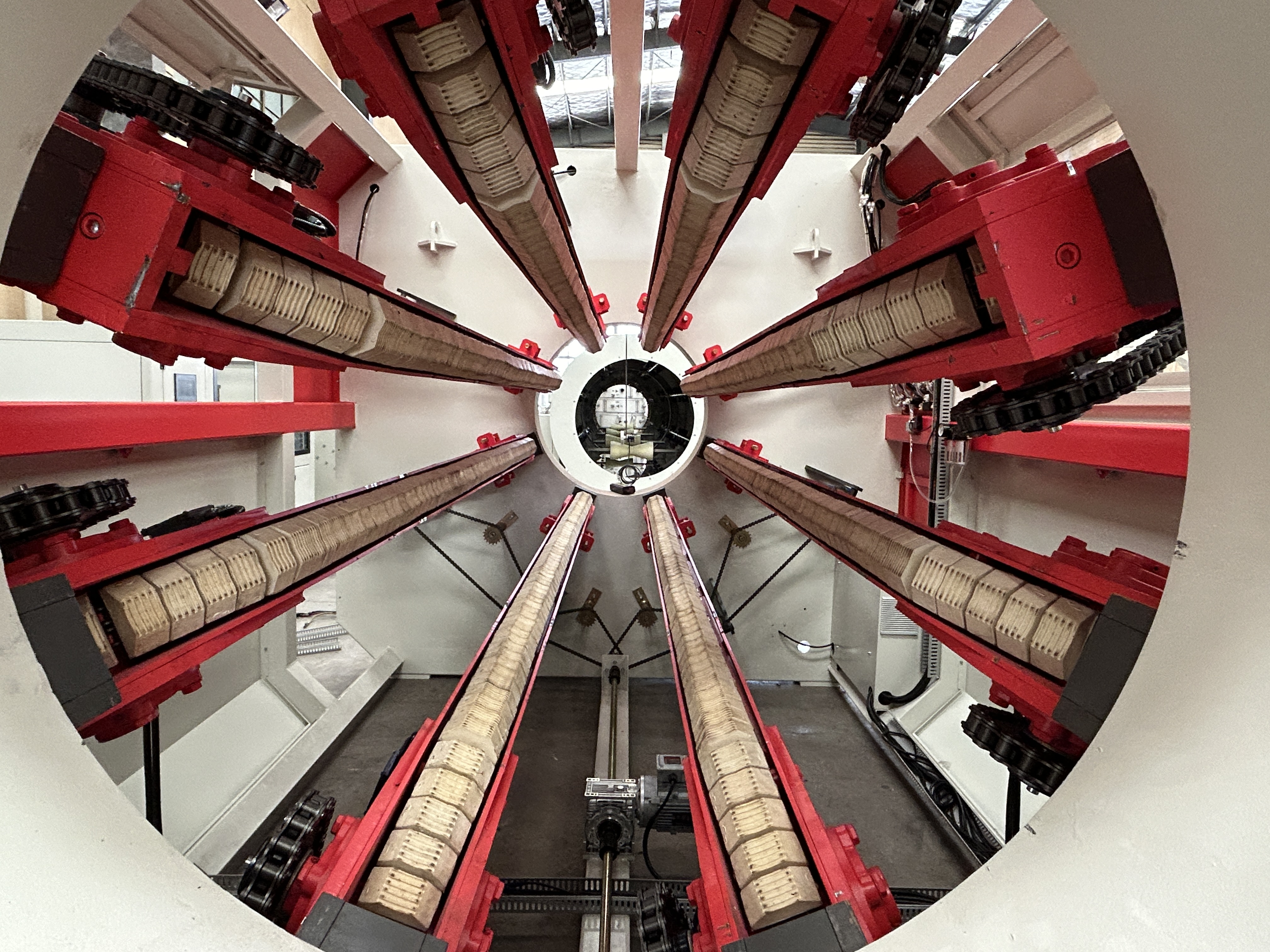

OPVC /UPVC Pipe Making Machine Production Line

PVC silent pipe is one of special designed UPVC pipe. It has highly noise reduction function. The U-PVC silent pipe often starts from 50mm and its mould design differ from the normal PVC pipes. It has rotations lines inside the pipe. Therefore the mould is rotating during the pipe production. It adopts 8 meters long vacuum tank ensuring enough cooling time of U-PVC pipe. The haul-offs guarantee the pipe moving forward smoothly and stably. The gearbox and motor of our haul-offs is Redsun. Our cutter is panetary cutting system. And it has stacker to hold the finished pipe.

-

Hot sale 355-800mm PVC Pipe Extrusion Line with 92/188 110KW motor

For the large PVC pipe, it is often used in the industrial water supply pipe. It is widely used in the Saudi Arabia and middle east countries. For the large diameter pipe, its capacity can be up to 800-1000kg/h. We have much experienced in the large diameter PVC pipe. For this line, we adopt 92/188 110kw extruder to ensure the stable extrusion speed. The mould material adopts 40Cr with temperature sensor device. The motor is Siemens-beide(joint venture in China). It has 6 meters long vacuum tank and four caterpillar haul-offs.

-

500L Stainless Steel Plastic Mixer For Preparing WPC Proof Profile

The 500L heating mixer is without the cooling mixer part. It is much cost-effective and suitable for WPC profile production line. The raw material of wpc profile is wood and plastic. It needs the mixer to produce mixture of wood-plastic product and then send into the granulator machine. Only by this way, the product surface is even and smooth. Our 500L heating mixer used Siemens made in China motor and all the inner surface are stainless steel SUS304. It has been mirror polished and surface specific process. It ensure the smooth of the inner surface of the pot. This will largely decrease the electricity consumption during the daily production. Our mixer combination machine has 18 month warranty and lifelong after-sales service. If you need it, please don’t hestitate to contact me for more information.

-

Wood Plastic Decking Door Composite Lamination Making Machine/Embossing Machine

Brief Description of the wpc embossing machine

wpc embossing machine is hot sale in our company,according to your width of panel we can recommend suitable model for you.also you can choose one or two different patterns to emboss at same time,which can increase the efficiency greatly!

The machine is suitable for PVC, PE,PP and other WPC panels, bamboo, composite panels, wood panels, fiberboard, foam board and other outdoor, indoor decorative embossing plate, embossed by this machine, it obtained three-dimensional , increase the beauty, improve product quality.It’s composed of machine frame, top & bottom heating device, temperature controller, top &bottom embossing roller, control box, cycloid pinwheel reduction motor, hydraulic system. -

180-400mm HDPE Pipe Extrusion Line

This line is making 180-400mm HDPE Pipe with 2cm wall thickness. We adopt 75/38 extruder with 160kw motor. It ensures 160kg/h capacity. The vacuum and cooling tank ensures the pipe become round and hard inside the tank. Another one cooling tank guarantee the high speed production. We equip three caterpillar haul-off machine and knife cutting. The special design of the mould and temperature adjustment device ensures the pipe with good surface and best performance.

-

400-710mm PVC Pipe Extrusion Line with 92/188 110KW motor

For the large PVC pipe, it is often used in the industrial water supply pipe. It is widely used in the Saudi Arabia and middle east countries. For the large diameter pipe, its capacity can be up to 800-1000kg/h. We have much experienced in the large diameter PVC pipe. For this line, we adopt 92/188 110kw extruder to ensure the stable extrusion speed. The mould material adopts 40Cr with temperature sensor device. The motor is Siemens-beide(joint venture in China). It has 6 meters long vacuum tank and four caterpillar haul-offs.

-

Factory sale 630-800mm HDPE Pipe Extrusion Line China Machine

For the large diameter HDPE pipe, it is often used in water supply or sewage pipe field due to its very thick wall. For the 630-800mm diameter pipe line, we adopt 120/38 350KW extruder to ensure its output capacity. Our motor is Siemens-beide(joint venture in China). It has very good quality and long lifeworking time. Meanwhile due to it is famous brand in the whole world, it has good after-sales service. Our vacuum tank is 9 meteres long with totally SUS304/3mm. This steel thickness ensures the tank strong and good vacuum effect. For the large diameter with thick wall HDPE pipe, this line also equips with two 9 meters long spraying cooling tank. We used good quality sprazzles ensuring the spraying water even and continuous. For the cuttting system, it equips two kinds of cutting including knife cutting and planetary cutting. The cuttting system has automatic adjustment system. It could be adjusted according to different producing pipe size. Our machine is totally automatical that can start production by one buttom. It makes that production without workers come true.

-

Good Quality UPVC Silent Pipe Extrusion Line 50-160mm Hot Sales

PVC silent pipe is one of special designed UPVC pipe. It has highly noise reduction function. The U-PVC silent pipe often starts from 50mm and its mould design differ from the normal PVC pipes. It has rotations lines inside the pipe. Therefore the mould is rotating during the pipe production. It adopts 8 meters long vacuum tank ensuring enough cooling time of U-PVC pipe. The haul-offs guarantee the pipe moving forward smoothly and stably. The gearbox and motor of our haul-offs is Redsun. Our cutter is panetary cutting system. And it has stacker to hold the finished pipe.