-

LB-Single shaft shredder for plastic melt lumps

Model Pipe diameter(mm) Extruder Extruder Power Capacity(kg/h) LB-63 20-63 SJSZ65/33 55 AC 150 LB-110 20-110 SJSZ65/33 55 AC 150 LB-160 75-160 SJSZ75/33 90 AC 280 LB-250 90-250 SJSZ75/33 110 DC 350 LB-315 110-315 SJSZ90/33 160 DC 450 Single screw extruder machine The extruder are crafted with top brand components to ensure production stability, efficiency and machine durability. Our extruder allocate international standard single screw and barrel. The screw has strong rigidit... -

LB-Co-extrusion double layer wpc profile extrusion line

This unit is professional line to produce WPC (PP/PE) profile product, including chairs,floors and trash can series profile product.

The line compounds domestic and abroad technology, having characters of high automatic level, steady performance, large output and high efficiency. It has two extruders. One is making the inner layer. Another is making outer layer. The outer layer color can be changed randomly.

-

LB-20-63mm HDPE Pipe Extrusion Line

As the world developed, more and more countries invest more time and money on the infrastructure area. Therefore small pipes with diameter from 20-63mm HDPE pipe sells well in the western country especially the African country. Our 20-63mm HDPE pipe has high speed and low speed extrusion line with different extruder and motor in order to satisfy the demand of new factory and mature factories.

-

LB_75-315mm PVC Pipe Extrusion Line

PVC pipe is widely used in the whole world as water supply pipe or electrical conduit pipe. As surveys review that 100-160mm pvc pipe sells well in the market. Therefore more and more pipe factory needs the 75-315mm pvc pipe line. For this line we adopt high output extruder and siemens motor. All the components are famous brand and good quality.

-

LB-Embossed outdoor wpc profile extrusion line

The wpc profile has two kinds. One is pvc profile + lamination machine. One is PP/PE +wood powder. The raw material different, the layout of the whole extrusion line differ. Recent years, as the wood powder price rising, more and more manufacture produces pvc profile and laminate different film on it. By this way, the cost of the product has decreased and more situation can use. The pvc type wpc is mainly used as decoration. The PP/PE type wpc is mainly used as wpc floor.

-

LB_32-63mm PVC Pipe Extrusion Machine

This line is applied to produce 32-63mm pvc pipe. Its output capacity can be up to 400kg/h. This line adopt double stand design. It can make two pvc pipe at the same time. By this way, it highly increased the capacity. Our motor drive is Siemens-Beide. And the control cabinet and the haul-off machine have smart control.

-

LB-Reliable Factory produced waste plastic crusher

During the adjusting of the pipe or profile extrusion line machine, it often produces some waste products. We could send back the crushing flakes or powder into feeder. After that procedure, the beginning waste material will be plasticizing again and become perfect pipes. It is an economical way and effectively saving the budget of the raw material.

-

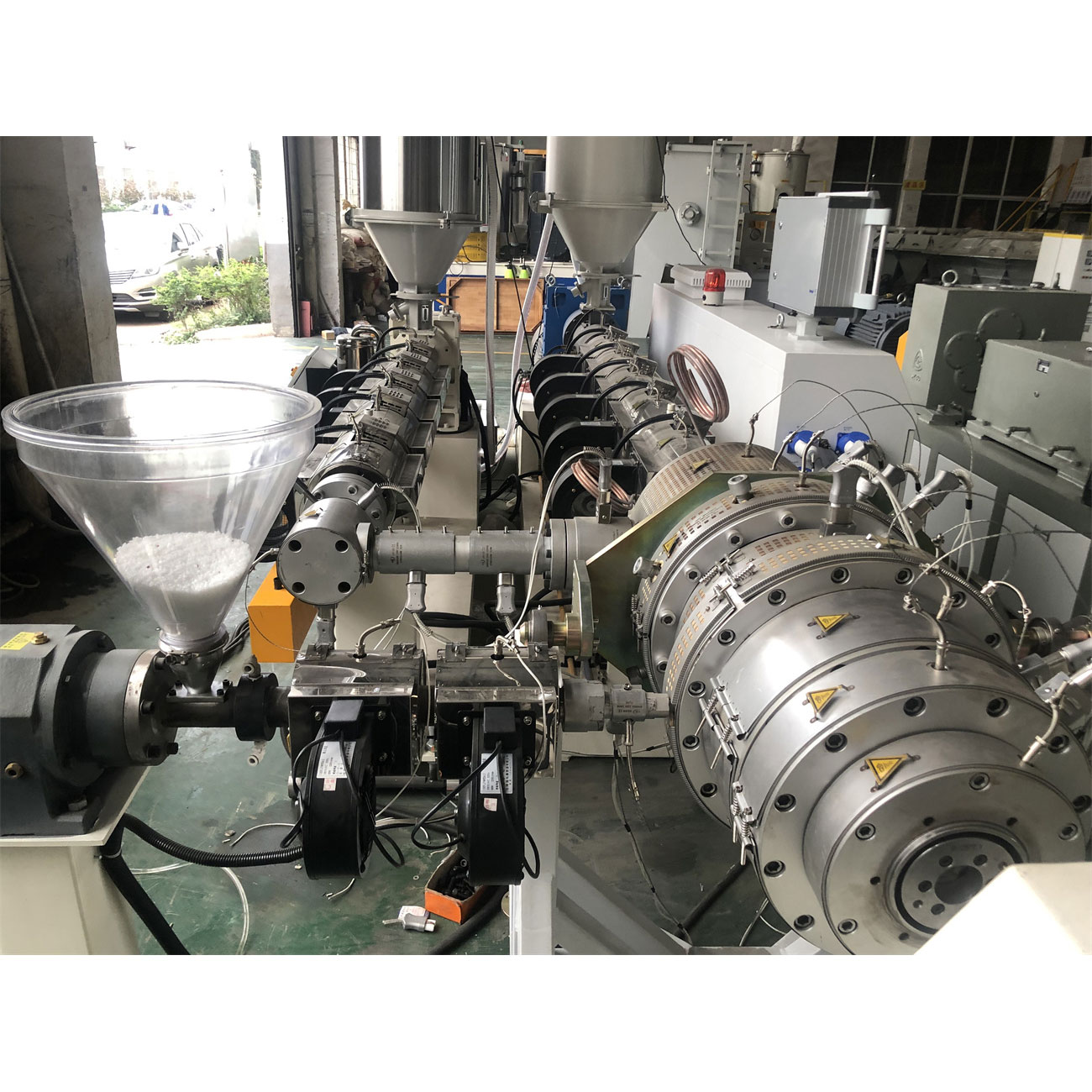

LB_75-315mm HDPE Multi layer Pipe Extrusion Machine

With vast experience in the HDPE single and multi layer pipe extrusion field, our company made a 75-315mm HDPE pipe extrusion machine line. We adopt 160kw motor, Flender gearbox, Siemens PLC control system. For the multi layer HDPR pipe, inner and outer layer used virgin material and the medium layer used recycling material. It is a good way to save the capital of the raw material.

-

LB-Plant Waste PET bottle plastic washing machine equipment

The waste pet bottle recycling line is transferred the waste into clean flakes by crushing and washing. PET material are crushed by granulator, washed by cold water in PET Separation Tank and separated from floating plastics. Cold washed flakes are washed with chemical solution added hot water in Hot Washing Tank. They are cleaned intensively with high speed and friction in Horizontal Centrifuge and rinsed in second Separation Tank by cold water. Clean PET flakes are transferred to Dynamic Centrifuge and residual moisture of flakes are reduced to 1%.

-

LB-waste plastic PE PP film/ bags recycling machine

This waste plastic PE PP film/ bags recycling machine is designed and manufactured by Langbo Machinery, which is widely used for waste plastic PE/LDPE/LLDPE film, PP woven bag, PP Jumbo bag, shopping bag etc.

The waste dirty material go through crushing, washing, drying process will turn to be clean flakes for pelletizing. The line can be displayed “L” or “U” shape according to clients’ workshop.

We can also customize the washing line components according to client’s material and product requirement. -

LB-Manual and automatic PVC pipe socket making machine

This line provides manual and automatic PVC pipe socket making including “U” or “R” sockets. Mostly it is following the extrusion line, matching with slotting or screwing machines. It can also work separately. Our belling machine has two heating ovens. Before belling, the pipes will be heated in the heating oven. And when the pipes sending to belling, another pipe will be sent to heating. Therefore, the line has high output and fast working speed.

-

LB-PVC/PE/PP grinder/plastic pulverizing/milling machine for sale

The plastic grinder is usually used in plastic recycling processing. Before starting to extrude perfect pipes, the machine line will produce many waste plastics. The waste plastics, if throw out will be bad for the environment and increase the cost. The crusher can make the waste material into flakes. The grinder can make the flakes into powder. And then the powder will be transported for further processing such as mixing or extrusion.