-

LB-Factory Supply Cheap plastic agglomerator

The waste plastic being fed into the pot of machine, the high-speed rotating blade and the fixed blade shear the materials by rotation, so that the material will soon be cut into pieces, chopped or sheet of material under centrifugal force rotation of the cutter

-

LB-CE ISO 200-400mm high speed and high output 80/156 PVC Pipe Extrusion Line

For the 200-400mm pipe with high speed and high output demand, we adopt 80/156 extruder for the extrusion line. We adopt 110DC motor power. The average output of this line is about 600kg/h. We employ control system to control the extruder. All temperature modular and electrical parts such as air switches, contacts, relays, timers will also be SIEMENS.

-

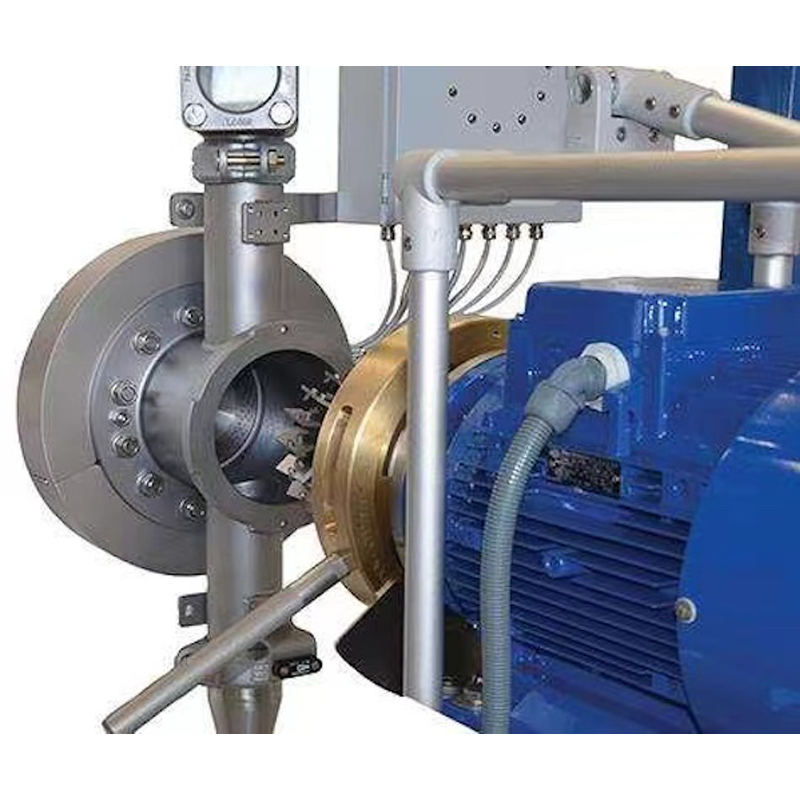

LB-PP/PE Underwater Cutting Granulating Machine Line

The LBUW series cutting granulating line machine with extrusion and pelletizing system is especially mature and complete. It is suitable for the recycling and re-pelletizing job of rigid plastic scraps. Due to the physical feature of viscous and easy to attached together, we offer underwater cutting granulating method. The final produced products are pellets/ granules easy to store and transportation.

-

LB-Factory Price Water Slide Cutting Granulating Machine With CE approval

For the waste plastics, the best process method is recycling and granulating. The principle of water slide cutting pelletizing method is plastics extruding through the extruder and cooling by the cold running water. This way is conducive to transporting the plastic strand because the running water provides the moving force. It won’t break halfway.

-

LB-PVC Pipe Production Line

LB Machinery offers complete production line for PVC/UPVC pipe ranging from 16mm to 800mm. This production line can be used for making pipes with different diameters and wall thickness in the aspects such as the electrical conduit, agricultural and constructional plumbing.

-

LB-Co Extrusion ABA PPR Glass-fiber Pipe Extrusion Line

At present, the PPR pipes reinforced with fiberglass in the market is more popular and sells well. Therefore, the PPR glass-fiber pipe extrusion line is a potential opportunity. LB Machinery has focused on the PPR glass-fiber pipe extrusion for several years. We offer top-brand components and good quality particles for the machine.

-

LB-PLC control High Capacity PVC Pipe Production Line

PVC pipe extruder machine is mainly used in the manufacturing of the UPVC and PVC pipes with various pipe diameters and wall thickness such as agricultural and constructional plumbing, water supply and drain etc.

This set is composed of conical twin-screw extrude, vacuum calibration tank, haul-off machine, cutter, stacker etc. The screw extruder and traction machine adopt imported AC frequency control device. The vacuum pump and traction motor both adopt advanced components. The haul-off machine has several models, such as two-claw, three-claw, four-claw, six-claw etc. It has visual blade and different cutting type.The unit is of reliable performance and high production efficiency.

Our machine can produce the PVC pipe with diameter from 16mm to 630mm

-

LB-CE ISO 16-630mm PVC Pipe Extrusion Line With 22-160KW Extruderpvc pipe making machine

Producing high capacity pvc pipes needs to undertake more energy consumption and raw material costs. On this occasion, our company is continuously being optimizing its pipe extrusion solutions during recent years. The method we adopt: first-rate energy balance between high output and pipe extrusion with maximum effectiveness. All the extrusion lines from LANGBO MACHINERY are based on one source_quality and service first. We accompany you from the initial idea to the finished product-reliable, competent and fair.

-

LB-WaterRing Cutting Granulating Line

This line is mainly used for producing pellets by waterring cutting method. In front of the extruder is a waterring granulator. After cutting, the round pellets was thrown into the water tank. Cooling and vibrating, the pellets were clean and dry. In the recent years, the sales market for pellets is also excellent. By waterring cutting granulating, the quality of the pellets is even and east to store.

-

LB-Strand Cutting Granulating Line

This line is mainly used for producing pellets. Through extruding, making stand, cooling and cutting into pellets, the storage of the pipes raw material is more convenient. In the recent years, the sales market for pellets is also excellent. Our granulating line used including extruder, cooling tank, air knife, pelletizer and vibration sieve. All the components are top-brand quality and long working lifetime.

-

LB-PE Large Pipe Extrusion Line

This line is mainly used for producing HDPE pipes with different diameters ranging from 630mm to 1400mm. The feature of HDPE pipe is resistant to high strength. This line offers energy-saving motor and automatic control system. High standard manufacture and details apply for better operation and maintenance.

-

LB-Double Strand PVC Pipe Extrusion Line

During producing pvc small diameter of the pipe, double strand production line is usually adopted. By this way, the output is largely improved. The double strand keeps perfect balance between wide diameter range capability and productivity.