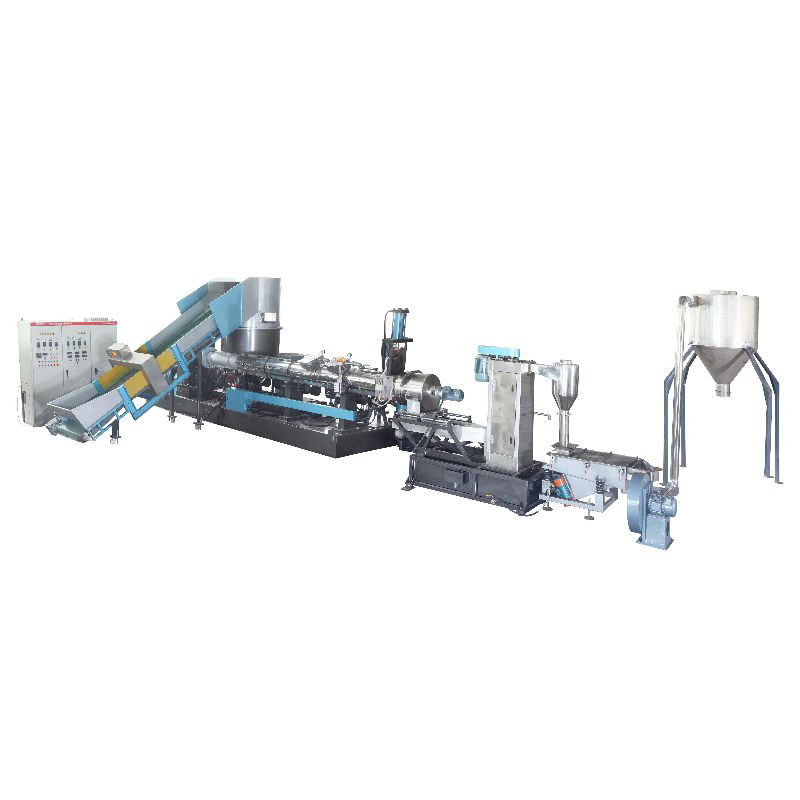

Professional Design Plastic Recycling Granulating Line - LB-Water slide String granulating line – Langbo

Professional Design Plastic Recycling Granulating Line - LB-Water slide String granulating line – Langbo Detail:

LB Machinery offers high efficiency strand cutting granulating line. A perfect combination provides a high efficiency running between extruder and downstream equipment. Our strand cutting granulating line ensures high product specification and high production yields.

Extruder:→Water Bath Cooling:→Air Knief Drying:→Rotor of Pelletizer:→Vibrating Sieve→Collection Bag

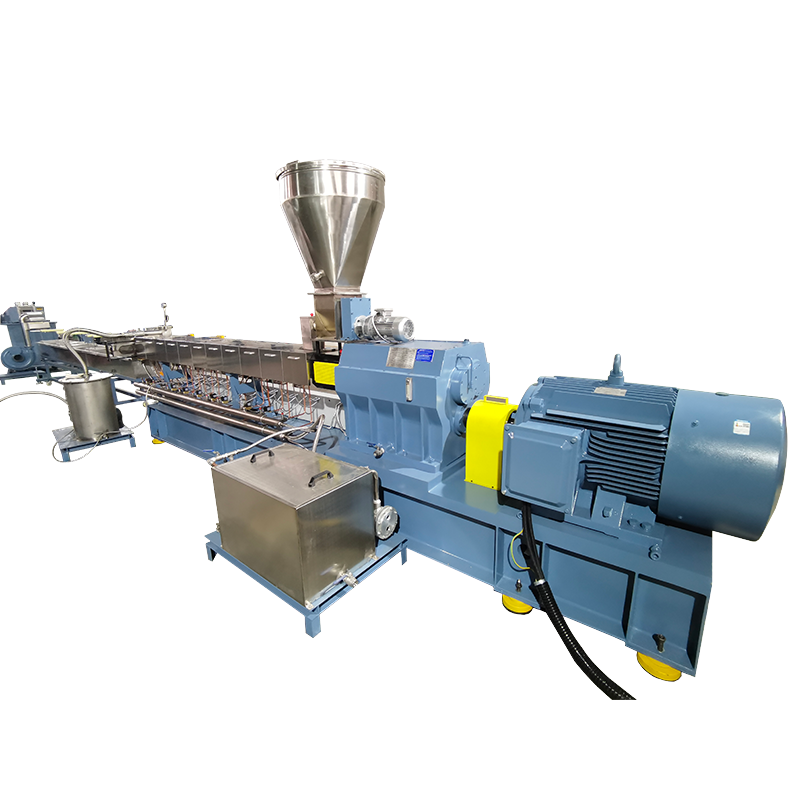

Extruder:

LB Machinery offers single screw extruder for the PE or PPR strand cutting pelltizing as well as twin screw extruder for PVC strand pelletizing line. We pull off the raw material into the feeder and extrude plasticizing stand.

Water Bath Cooling:

In the water bath, the raw material strand was cooled and moving forward together with the flowing water. During the forward movement, the plasticizing strand harden and cooling.

Air Knief Drying:

Getting through the water bath cooling, the plasticizing strand are dried by the air knief. The blowing wind takes away the excess moisture that is the preparation for the pelletizing.

Rotor of Pelletizer:

Our pelletizer utilize the helical blades of bolt-on blades. The blade runs at a high speed continuously to cut out the uniform-sized granules.

Vibrating Sieve

The granules out the pelletizer go through the vibrating sieve. Under the high frequency vibrating, the granules can be figure out into big, medium and small. Through processing, we can get particles of uniform size.

Screen Changer:

It is optional. The screen changer is used to filter the impurities. If the granulated material is purity, the screen changer is unnecessary.

Equipment Color:

We offer customized equipment color. Plenty of machine color is available.

Product detail pictures:

Related Product Guide:

To create extra value for customers is our enterprise philosophy; buyer growing is our working chase for Professional Design Plastic Recycling Granulating Line - LB-Water slide String granulating line – Langbo, The product will supply to all over the world, such as: Mozambique, Slovakia, Latvia, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are satisfactory reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Problems can be quickly and effectively resolved, it is worth to be trust and working together.