Renewable Design for Plastic Flake Pelletizing Line - LB-Water Ring Granulating Line – Langbo

Renewable Design for Plastic Flake Pelletizing Line - LB-Water Ring Granulating Line – Langbo Detail:

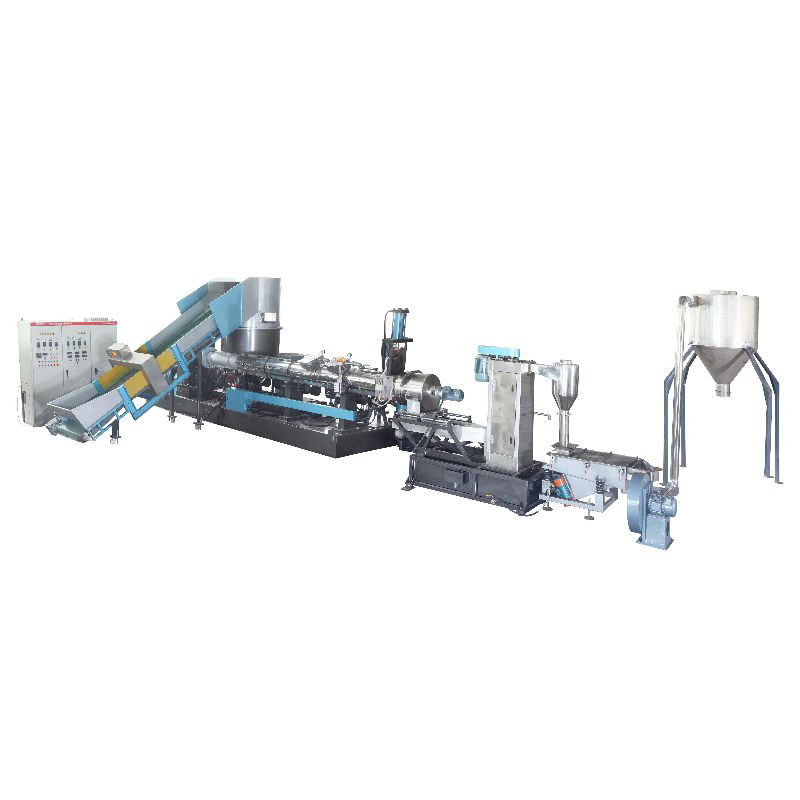

Langbo Machinery manufactures the specific water ring pelletizing line, which combines high efficiency running and stable productivity. Based on our mature technology and close contact with our customer we provide not only validated pelletizing equipment but also comprehensive solution.

Extruder:→Water Ring Cutting:→Vibrating Sieve→Dehydrator→Collection Bag

Water ring granulating line belongs to the concept of hot cut pelletizing method. Polymer exiting extruder passes into an annular die. At the die face, the molten polymer will be cut by flexible blades in air. After cutting, molten pellets are thrown into a ring of falling water. In water the pellets are cooled and transported. The cutting, cooling and transporting condition define different pelletizing methods and dispose unique pelletizing equipment.

Water ring granulating system produce rounded but flat pellets with the shape of similarly aspirin tablets. It is because of the specific cutting process.

As the polymer exits from the multiple holes, the rotating knives cut the polymer and throw outward into the water ring chamber. The water cools the pellets and transports them to vibration sieve filtration to check the quality of the pellets. Only the pellets with stipulated size can be transported to the centrifugal dryer for drying. According to the character of the polymer, the cooling process could be improved.

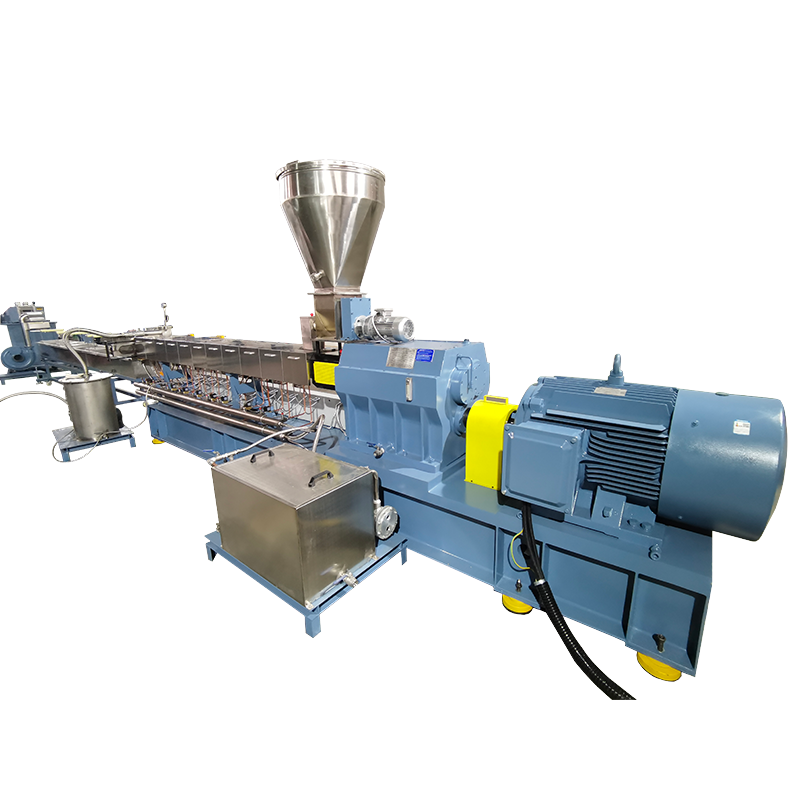

➢ Extruder:

➢ Water Ring Cutting:

➢ Vibrating Sieve

➢ Dehydrator

➢ Collection Bag

➢ Screen Changer:

➢ Equipment Color:

Die Face Cutter_Waterring_Pelletizing

die face pelletizing

granulating with die face cutting

Hydraulic Screen Changer_Pellectizing_WR

two stage extrusion water ring pelletizing

water ring pelletizing chamber

Product detail pictures:

Related Product Guide:

It adheres to the tenet Honest, industrious, enterprising, innovative to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for Renewable Design for Plastic Flake Pelletizing Line - LB-Water Ring Granulating Line – Langbo, The product will supply to all over the world, such as: Honduras, Thailand, Melbourne, Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner for you!

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,