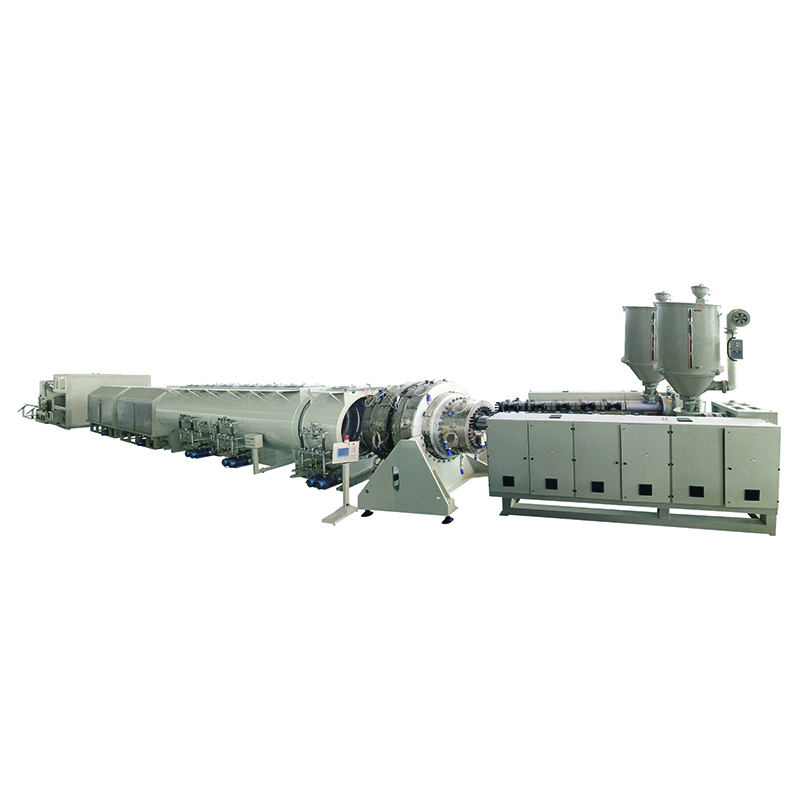

Short Lead Time for Diy Plastic Pelletizer - LB-Water slide String granulating line – Langbo

Short Lead Time for Diy Plastic Pelletizer - LB-Water slide String granulating line – Langbo Detail:

LB Machinery offers high efficiency strand cutting granulating line. A perfect combination provides a high efficiency running between extruder and downstream equipment. Our strand cutting granulating line ensures high product specification and high production yields.

Extruder:→Water Bath Cooling:→Air Knief Drying:→Rotor of Pelletizer:→Vibrating Sieve→Collection Bag

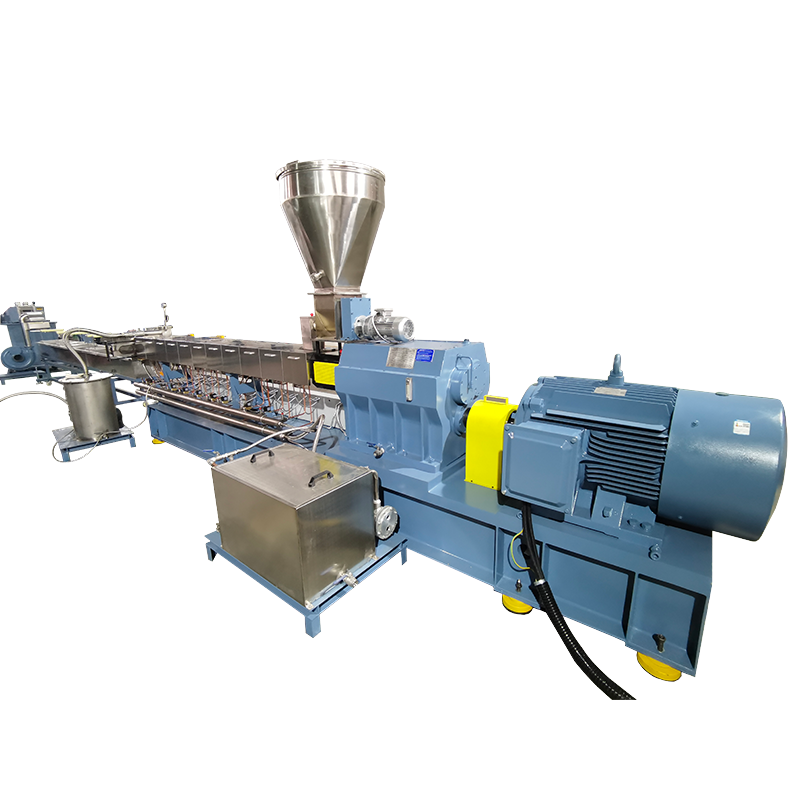

Extruder:

LB Machinery offers single screw extruder for the PE or PPR strand cutting pelltizing as well as twin screw extruder for PVC strand pelletizing line. We pull off the raw material into the feeder and extrude plasticizing stand.

Water Bath Cooling:

In the water bath, the raw material strand was cooled and moving forward together with the flowing water. During the forward movement, the plasticizing strand harden and cooling.

Air Knief Drying:

Getting through the water bath cooling, the plasticizing strand are dried by the air knief. The blowing wind takes away the excess moisture that is the preparation for the pelletizing.

Rotor of Pelletizer:

Our pelletizer utilize the helical blades of bolt-on blades. The blade runs at a high speed continuously to cut out the uniform-sized granules.

Vibrating Sieve

The granules out the pelletizer go through the vibrating sieve. Under the high frequency vibrating, the granules can be figure out into big, medium and small. Through processing, we can get particles of uniform size.

Screen Changer:

It is optional. The screen changer is used to filter the impurities. If the granulated material is purity, the screen changer is unnecessary.

Equipment Color:

We offer customized equipment color. Plenty of machine color is available.

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Short Lead Time for Diy Plastic Pelletizer - LB-Water slide String granulating line – Langbo, The product will supply to all over the world, such as: South Korea, Nepal, Vancouver, because of our company has been persisting in the management idea of Survival by Quality, Development by Service, Benefit by Reputation . We fully realize the good credit standing, the high quality products, the reasonable price and the professional services are the reason that the customers choose us to be their long-term business partner.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!