Short Lead Time for Plastic Tube Making Machine - LB-PVC Wall Panel Extrusion Line – Langbo

Short Lead Time for Plastic Tube Making Machine - LB-PVC Wall Panel Extrusion Line – Langbo Detail:

LB Machinery PVC Wall Panel Extrusion Line

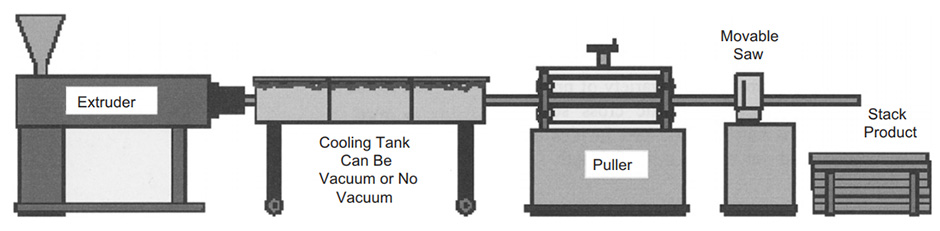

LB Machinery offers complete extrusion line for pvc wall panel tailored to the drawings of customers. Our wall panel extrusion mould is manufactured and regulated by experienced expert conformed to national standard. Our wide wall panel caterpillars hauling-off allocates rocket arm providing sufficient driving force and moving speed. The saw cutter is controlled by PLC humanized machine and easier operation. We offer top brand machine components ensuring the durability and productivity.

➢ Mixer

PVC resin and other additives can be bought and mixed together by customers themselves according to formula and the application. For the wall panel production(PVC profile), high quality mixer is necessary and essential.

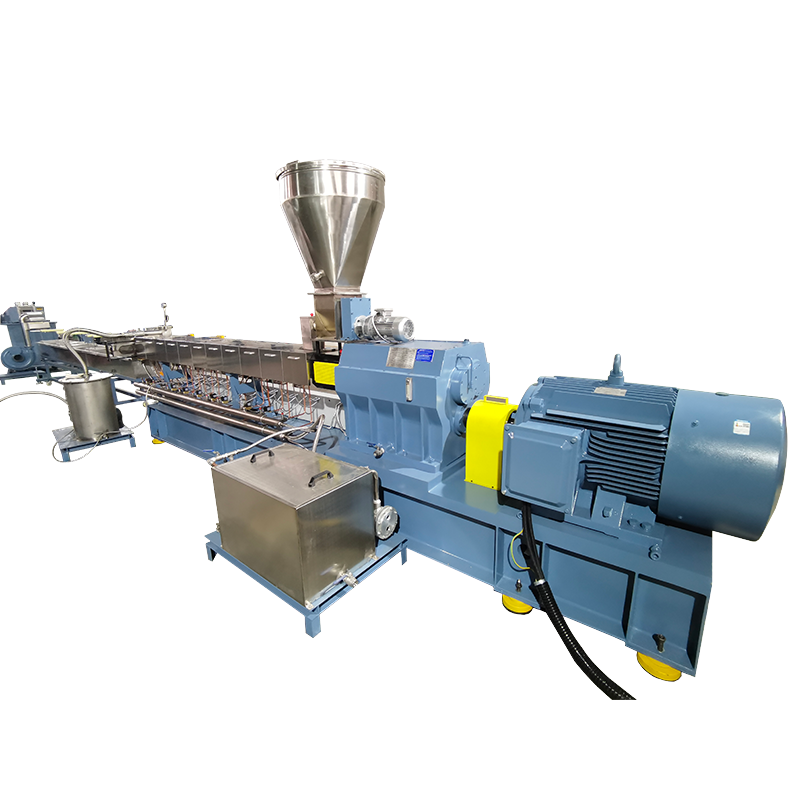

➢ Conical twin screw extruder machine

Due to the heating sensitivity feature of PVC, we adopt high-quality conical twin screw. In the processing, the rotation and plasticizing is temper and precision.

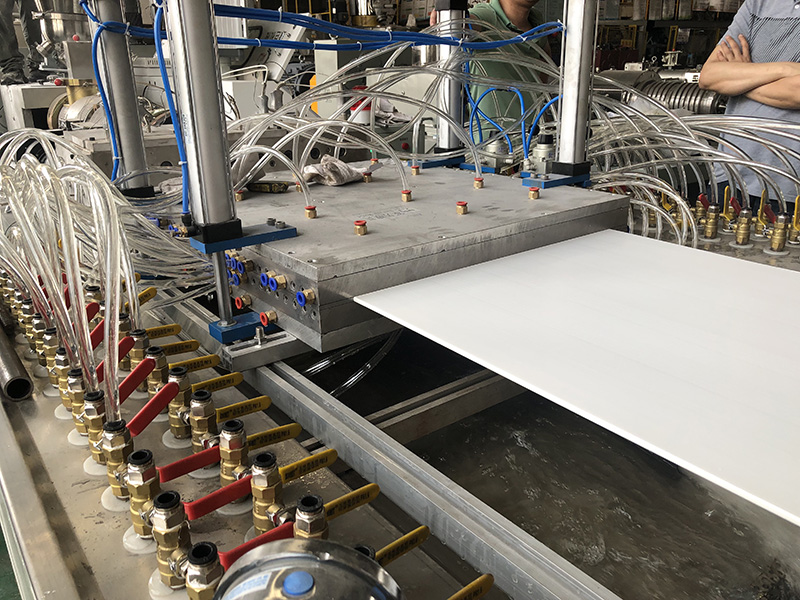

➢ Calibration table

We offer 8-12m calibration table ensuring sufficient cooling and solidification. Twelve sprinklers are continuously watering on the wall panel profile.

➢ Haul off (puller) machine

Our wide wall panel caterpillars hauling-off allocates rocket arm providing sufficient driving force and moving speed.

➢ Cutter machine

The saw cutter is controlled by PLC humanized machine and easier operation.

➢ Extrusion coating and lamination

The extrusion lamination machine is used to coating on the wall panel profile. After processing, the panel will have good-looking and wear-resisting consistent to different application.

Cutting unit

Haul-off unit

Laminator

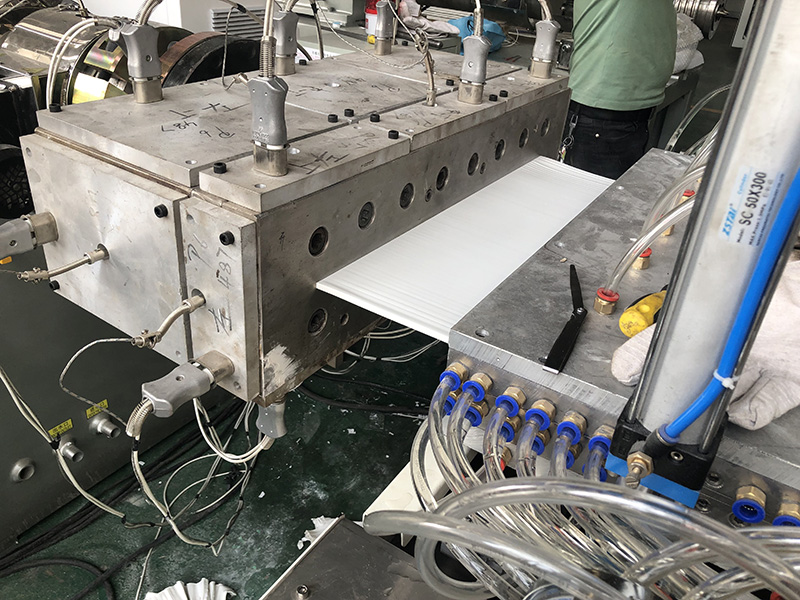

Profile mould

Profile vacuum tank

Wide board product

Product detail pictures:

Related Product Guide:

Our pursuit and company intention is usually to Always fulfill our purchaser requirements. We go on to acquire and layout excellent high quality products for both our previous and new consumers and realize a win-win prospect for our customers too as us for Short Lead Time for Plastic Tube Making Machine - LB-PVC Wall Panel Extrusion Line – Langbo, The product will supply to all over the world, such as: Burundi, Pakistan, Accra, We have excellent engineers in these industries and an efficient team in the research. What is more, we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.