Wholesale Price Wide Wall Panel Production Line - LB-Wide Panel Extrusion Line – Langbo

Wholesale Price Wide Wall Panel Production Line - LB-Wide Panel Extrusion Line – Langbo Detail:

The process flow of this line is PVC powder + additive — mixing—material feeder—twin screw extruder— mould—calibration table—haul-off machine—laminating process—cutting machine—discharge rack.

Our wide panel extrusion line adopts conical twin screw extruder, which has degassing system to ensure the excellent material plasticization. The mould and calibration table adopt wearable material; the haul-off machine provide constant force running stably; our laminating process is full of oil to increase lubrication. We adopt rotary knife to ensure the fixed length of the panel profile.

| Model | LB180 | LB240 | LB300 | LB600 |

| Max width of products(mm) | 180 | 240 | 300 | 600 |

| Screw Model | SJ55/110 | SJ65/132 | SJ65/132 | SJ80/156 |

| Motor power | 22KW | 37KW | 37KW | 55KW |

| Cooling Water(m3/h) | 5 | 7 | 7 | 10 |

| Compressor(m3/h) | 0.2 | 0.3 | 0.3 | 0.4 |

| Total length(m) | 18m | 22m | 22m | 25m |

Conical Twin Screw Extruder

The screws are specifically designed and manufactured for the processing of dry pvc powder. High quality screws and barrel ensures long service time. Equipped with PLC control system on the board, it realized controlling the whole production line in the one site.

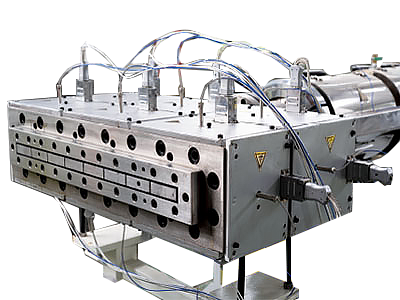

Plate Mould

Our profile mould has high flow performance due to the delicate channel design. Our mould is manufactured and inspected by advanced engineer with highest precision.

Calibration table

We have multi-dimension position adjustment system. With precious layout of water pumps and adequate calibration table, the wide panel will be rapidly shaping and cooling.

Haul-off machine

The force distribution along each caterpillars has sufficient hauling force. We offer good-quality rubber for the haul-off machine.

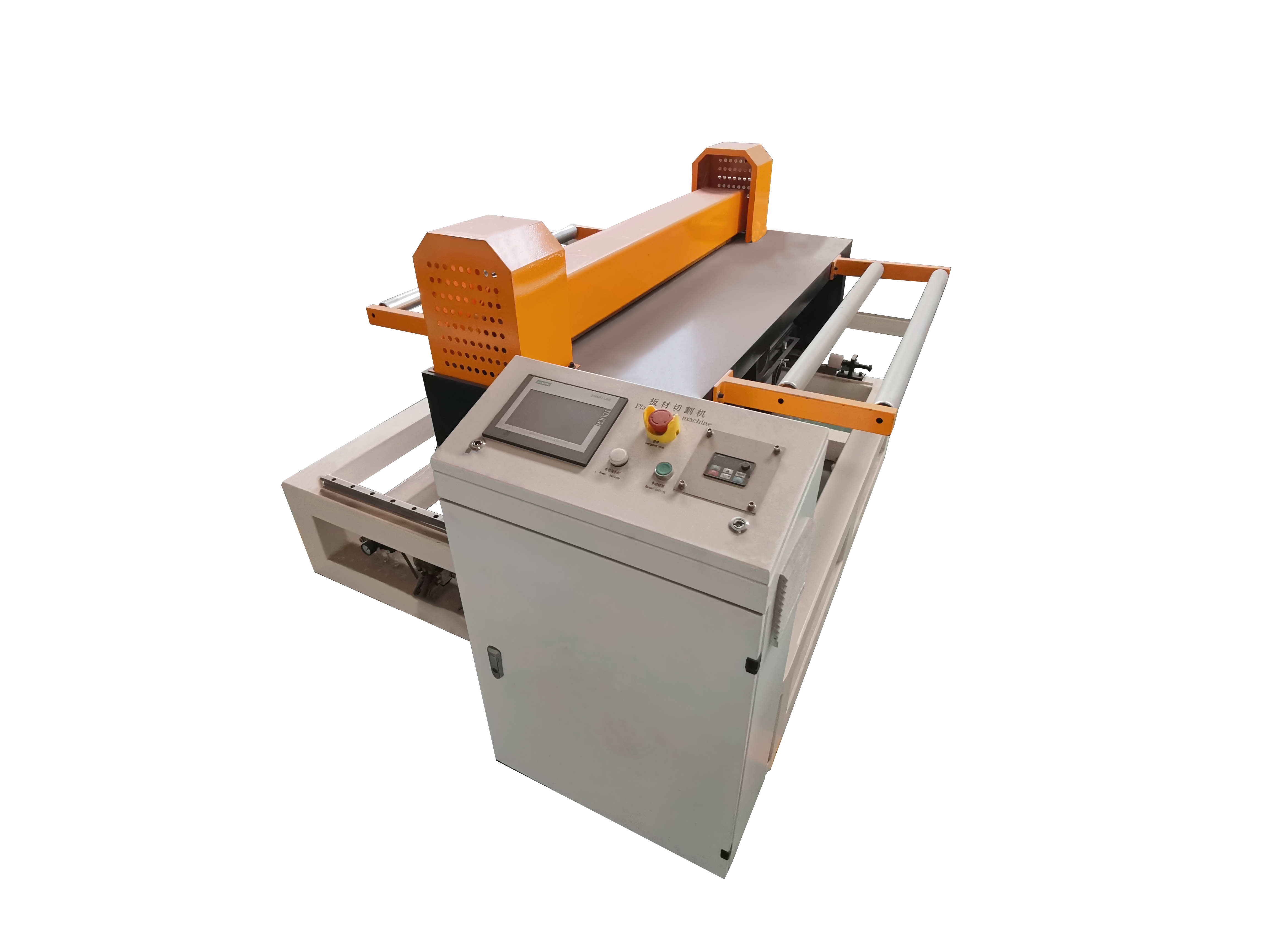

Rotary knife cutter

We offer rotary knife cutter for the wide panel extrusion line. It runs on the line track at the designated length of the panel. With its fast running on, the panel was cut. The whole cutting process is clean and easy-operation.

Pneumatic stacker

We offer stacker robot for the production line. It will pick up the cut and laminated wide panel from the board to the stacking area.

Product detail pictures:

Related Product Guide:

We can easily usually fulfill our respected customers with our very good high quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for Wholesale Price Wide Wall Panel Production Line - LB-Wide Panel Extrusion Line – Langbo, The product will supply to all over the world, such as: Kuala Lumpur, Cannes, Denver, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.